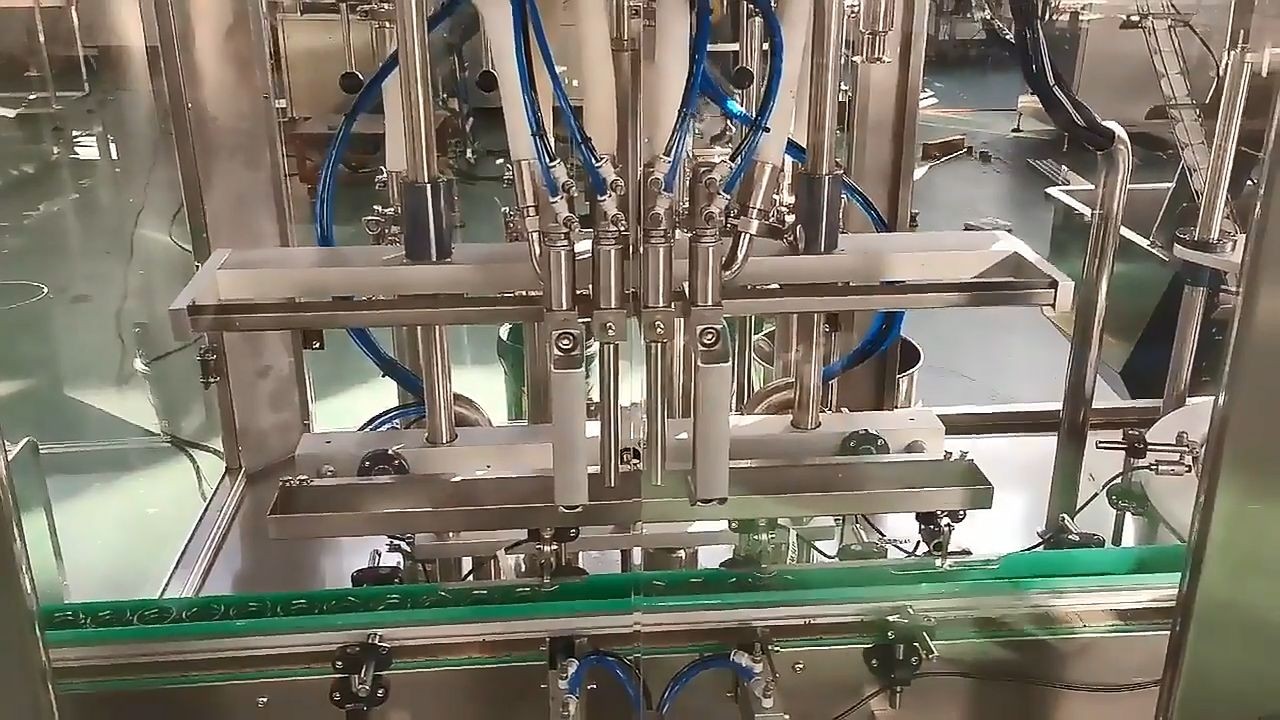

The automatic linear filling machine is design on the base of the VK-VF, it is also an extremely flexible filler capable of filling accurately and rapidly thin and middle viscosity liquids. and 2 heads or 4 heads are optional!

-- Schneider touch screen and PLC.

-- Accuracy +0.2% for 1000ML.

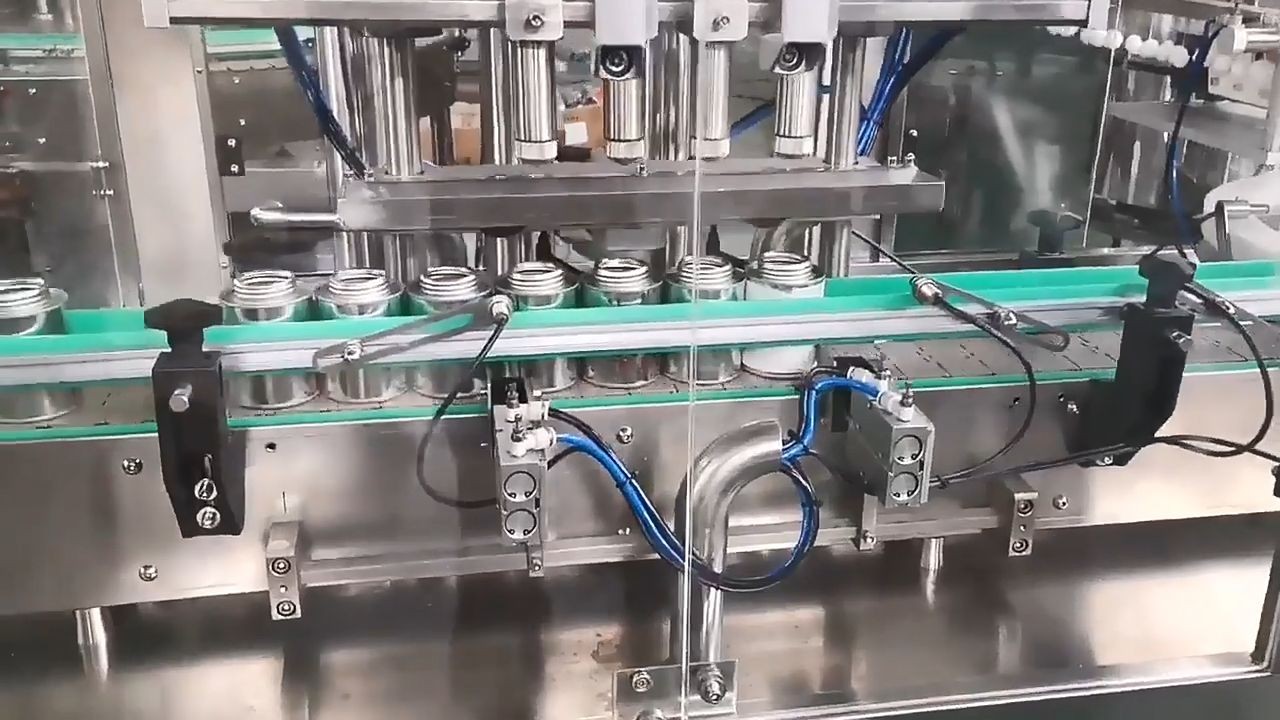

-- 304 Stainless steel construction and the material contact parts.

-- Controlled by panasonic servo motor or cylinder.

-- The filling blocked nozzles are anti drops, silk, and auto cut viscous liquid.

-- Easy to maintain, no special tools are required.

-- Diving nozzles for bottom up filling of foaming products if need.

| 1 | Speed | 450-1500 bottles/hour | ||

| 2 | Filling range | 100ml-500ml,100ml-1000ml,1000ml-5000ml | ||

| 3 | Measurement precision | ±1% | ||

| 4 | Working power | 220VAC | ||

| 5 | Air pressure | 6~8㎏/㎝² | ||

| 6 | Air consumption | 1m³/min | ||

| 7 | Power rate | 0.8kw | ||

| 8 | Other devices power rate | 7.5kw(air compressor) | ||

| 9 | Net weight | 320Kg | ||

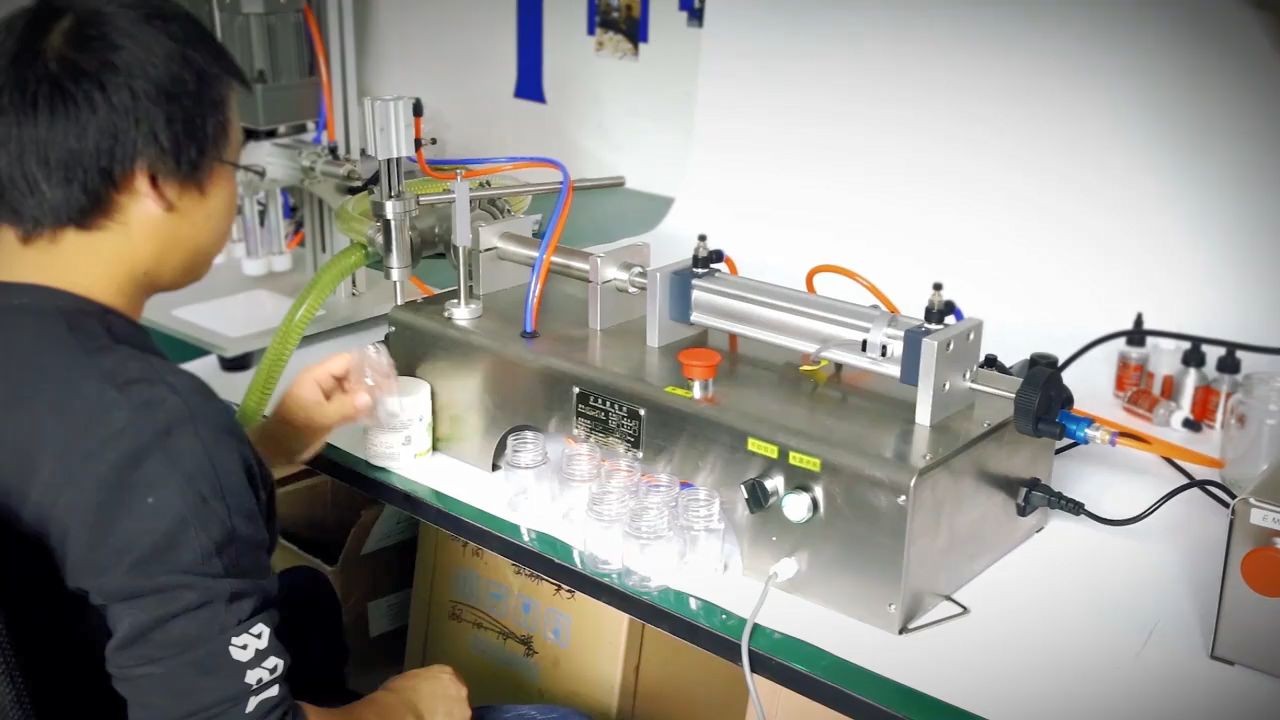

An automatic 2 nozzle economical liquid filler machine is a type of packaging machinery that is designed to fill liquid products, such as beverages, oils, and other similar products, into bottles or containers with a high degree of accuracy and efficiency. This machine utilizes two nozzles to dispense the liquid into the containers simultaneously, increasing the filling speed and reducing the time required to fill each container.

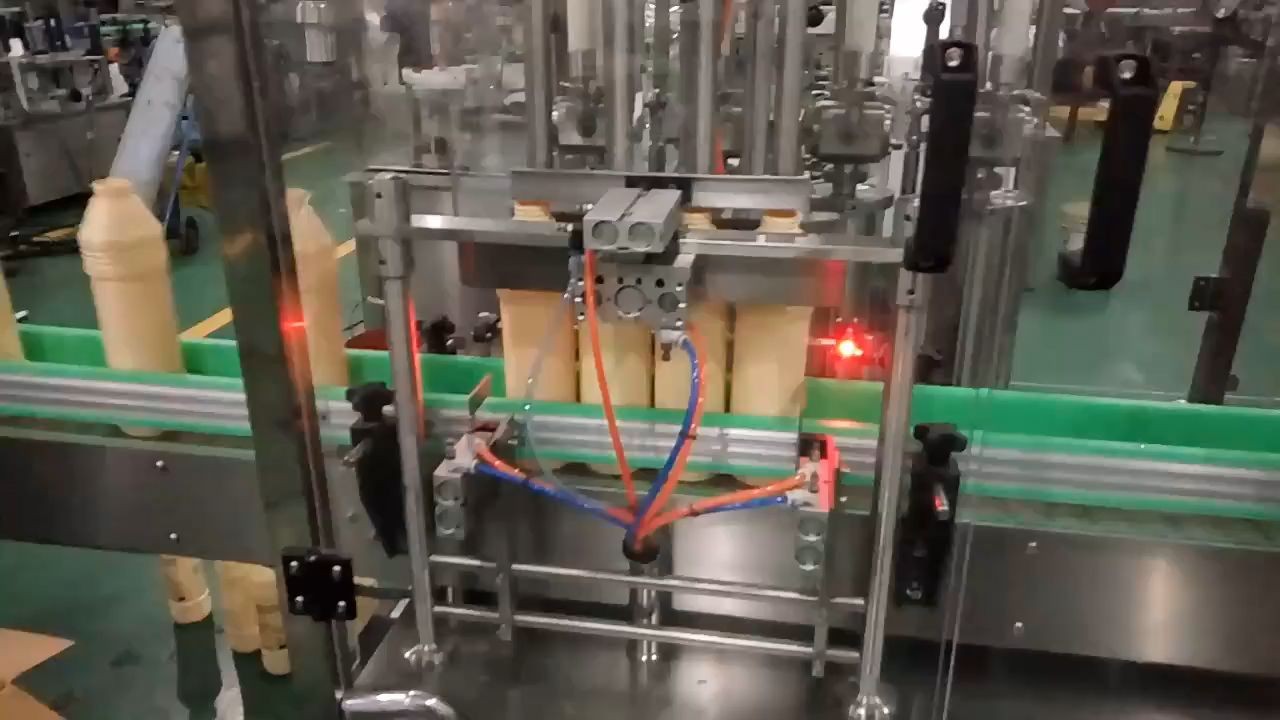

The automatic 2 nozzle economical liquid filler machine is ideal for use in the food and beverage industry, as well as in the production of other liquid products. It can fill bottles of various shapes and sizes, ranging from small travel-sized bottles to large containers, with volumes ranging from a few milliliters to several liters.

The filling process in the automatic 2 nozzle economical liquid filler machine involves several stages. First, the empty bottles are conveyed into the machine through a conveyor system, where they are aligned in a single file. The bottles then pass through the filling station, where the two nozzles are used to dispense the desired amount of liquid into each bottle simultaneously.

The machine can be programmed to fill the bottles to a specific level, ensuring consistent filling volumes and reducing the risk of overfilling or underfilling. Additionally, the machine can be adjusted to fill different bottle sizes and shapes, making it highly versatile and adaptable to different production needs.

One of the key benefits of the automatic 2 nozzle economical liquid filler machine is its high filling speed. With the use of two nozzles, the machine can fill two bottles at the same time, significantly reducing the time required to fill each container. This increases production efficiency and reduces labor costs.

Another benefit of this machine is its ease of use. The machine can be operated by a single operator, reducing the need for multiple workers and increasing productivity. The machine is also easy to maintain and clean, reducing downtime and increasing production efficiency.

In conclusion, an automatic 2 nozzle economical liquid filler machine is an essential tool for liquid product manufacturers who need to fill bottles or containers with precision and efficiency. With its high filling speed, versatility, and ability to fill multiple bottles at once, the machine offers a reliable and efficient solution to the challenges of liquid filling.