Labeling type: All around

Glue type: hot melt

Container diameter: 35mm-100mm

1.1).easy operation to adjust label cutting knife

1.2).vacuum drum made of high rigid material to reduce friction and static

1.3) rapid changeovers: modular design and quick release change parts have changeovers fast and easy in ten minutes

1.4).using handle to adjust the position of cutting knife is possible and exactly

1.5).vacuum manifold at the lower part of drum and cutter, made of heat & wear resistant material

1.6).automatic label length controller to adjust position of I-MARK

2. Label

label material: OPP, PVC, PAPER etc

label size:as demanded

labeling method: line type

3. Machine description

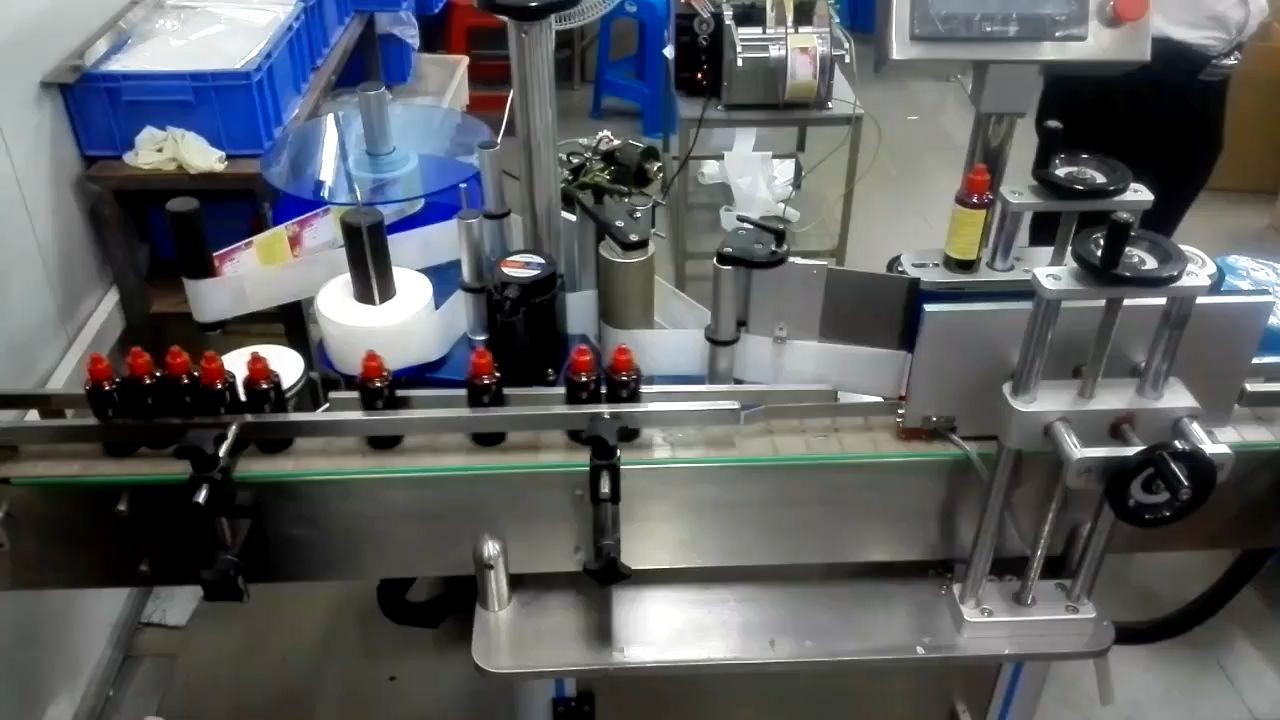

3.1) roll-fed type

3.2) label in-fed from label station is conveyed to label in-feed roll-er through label guide roller

3.3) sensors will check I-MARK of label automatically when label reaches label in-feed Roller

3.4) as soon as the position of I-MARK is confirmed, Encoder will adjust the operation speed of label in-feed roller and then appoint the label cutting position

3.5) label which has been cut is conveyed to vacuum drum

3.6) after checking label attached on vacuum drum by sensor, label is conveyed to glue roller and then inject hot melt on label

3.7) to adjust containers by in-feed star wheel and do labeling in roller zone for the first time and then labeling operation will be done perfectly by side belt.

4. Safety

4.1) control: PMC, inverter

4.2) safety attachments

Overload running safety equipment attached on driving zone

Stopper for abnormity operation of in-feed star wheel

No bottle fed (sensor check)

overload for bottle fed (sensor check)

no bottle no labeling

5. Main construct

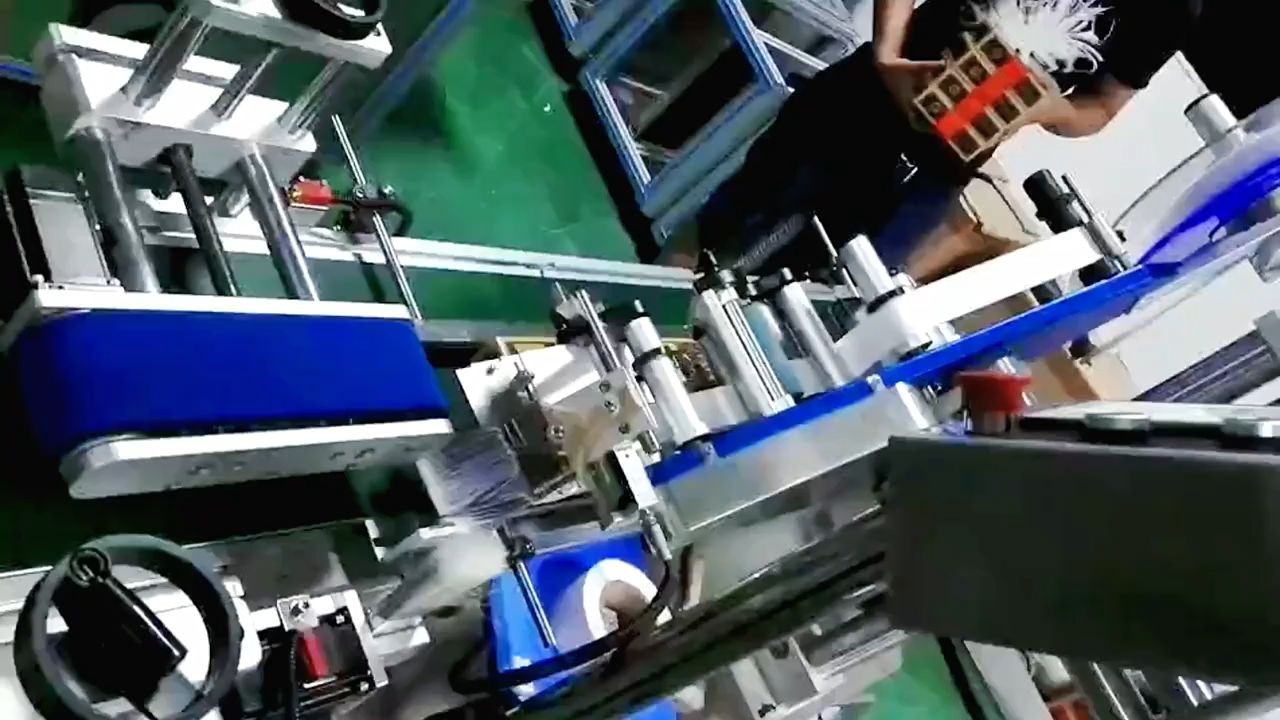

5.1) conveyor part

5.2) in feed star wheel part

5.3) label station

5.4) vacuum drum part

5.5) driving part

5.6) hot melt applicator

5.7) glue roller part

5.8) side belt part

5.9) label cutting part

5.10) label guide roller part

5.11) frame part

5.12) air and lubricate part

5.13) electric part

Features of Linear hot melt adhesive labeling machine

1, It applies to a row of paste volume, the use of local means glue, glue consumption of small, low running costs.

2, Due to the design of high-precision the machine capacity can reach high speed.

3, Marked station is the heart of the aircraft, designed to complete the standard trademarks station transmission constant tension; trademarks automatic correction; labeling speed (revolution speed of the machine and the speed of rotation of the synthetic bottle speed) internal matching; not send bottles marked function; glue function is not scale-free; bottle labeling before and after the replacement of the normal type;

4, the host used on home cam design to replace the bottle-type simple; nose tight card using pneumatic means to increase the convenience of the host.

5, The overall automation and control the use of PLC control, the servo system, the inverter system, temperature control systems and other needs with comprehensive control of the point.

6, Overload protection, security, protection of the design of complete, multi-point and fault protection device to ensure that the alarm sound and light man-machine safety.

7, Centralized lubrication system allows the operation of machinery lubrication components more simple, more normal, more to ensure that the machine life. The machine is simple and convenient maintenance.

8, a specially designed folder structure to ensure that trademarks are trademarks of trademarks has always been flexible in compacting the folder block.

9, Servo motor-driven traction trademark agencies, photoelectric color code detection and compensation structure of a trademark can be cut off to ensure that trademarks are timely, accurate, and neatly cut.

10, biaxial screw propeller institutions bottle into the bottle so that a more stable, high-speed into the bottle so much more smoothly.

11, Inflatable bottle of the local function is the quality of the container (grams) low, allowing users to reduce operating costs.

12, Double disk structure to ensure that the user feed the least time to replace the membrane, so that the effective production of longer, more productive machines.

13, specifically the constant tension of the membrane material detection and feedback control system ensures that the general membrane materials to achieve high quality labeling.