The overflow filling machine works by feeding the liquid through a specific pump or a top storage tank.Simultaneously. once the feeding is completed. a portion of the material returns to the liquid overflow tank via the overflow port to guarantee the filled bottle in same level. The depth of the overflow port in the container neck determines the container’s filling level, which is easily adjustable. The number of filing heads can be increased to meet production needs. it is ideal for filling low-viscosity, high-foaming goods in the chemical, food, pharmaceutical, and other sectors.

| Name | Automatic Overflow Filling Machine |

| Measurement precision | ±0.5%-1% for 1L |

| Capacity | 800b/h-7200b/h |

| Voltage | 220VAC 50/60hz |

| Air pressure | 4~6kg/cm² |

| Air consumption | 1m/min |

| Power | 1000w |

Main feature:

1. For some highly corrosive liquid products,this machine can adapt PTFE pump,PTFE hose and sealing material, so as to avoid the corrosive of the machine

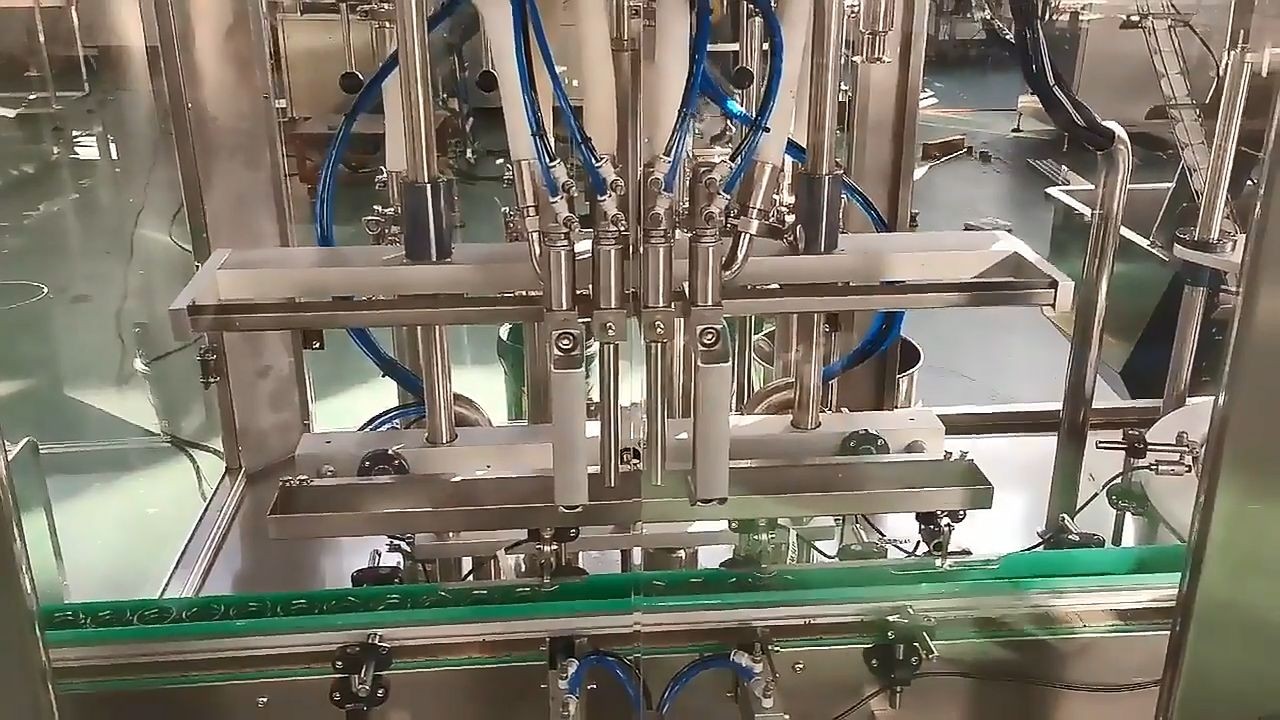

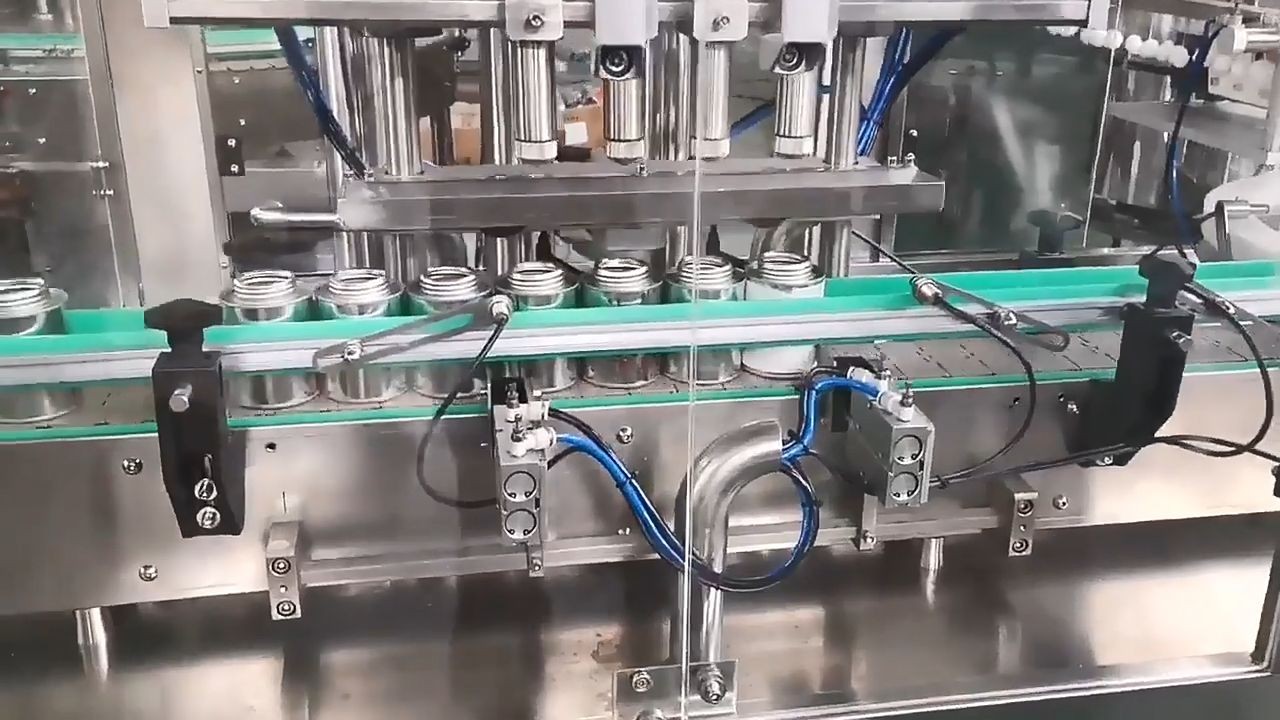

2. The parts in contact with the liquid conform to the GMP standard. When filling. the filling head extends into the bottle and the bottle is sealed to ensure that the liquid does not foam and overflow, and the liquid level in the bottle is consistent

3. The filling head has the function of sucking back, and there is no dripping phenomenon. The bottle is not in place and not filled, ensuring misoperation and keeping the work area clean.

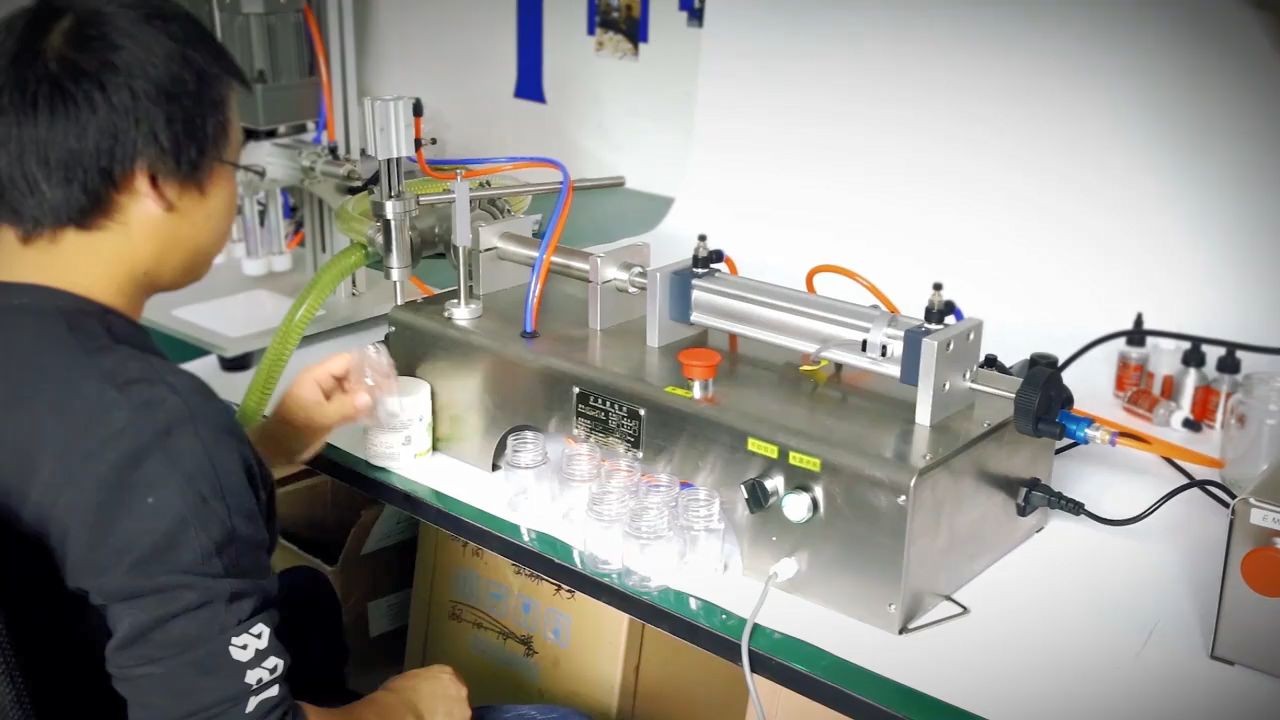

4. This machine has only one filling pump, one top tank and one side stand tank which can be equipped with 2~20 filling heads, and the output and filling volume can be adjusted if need.

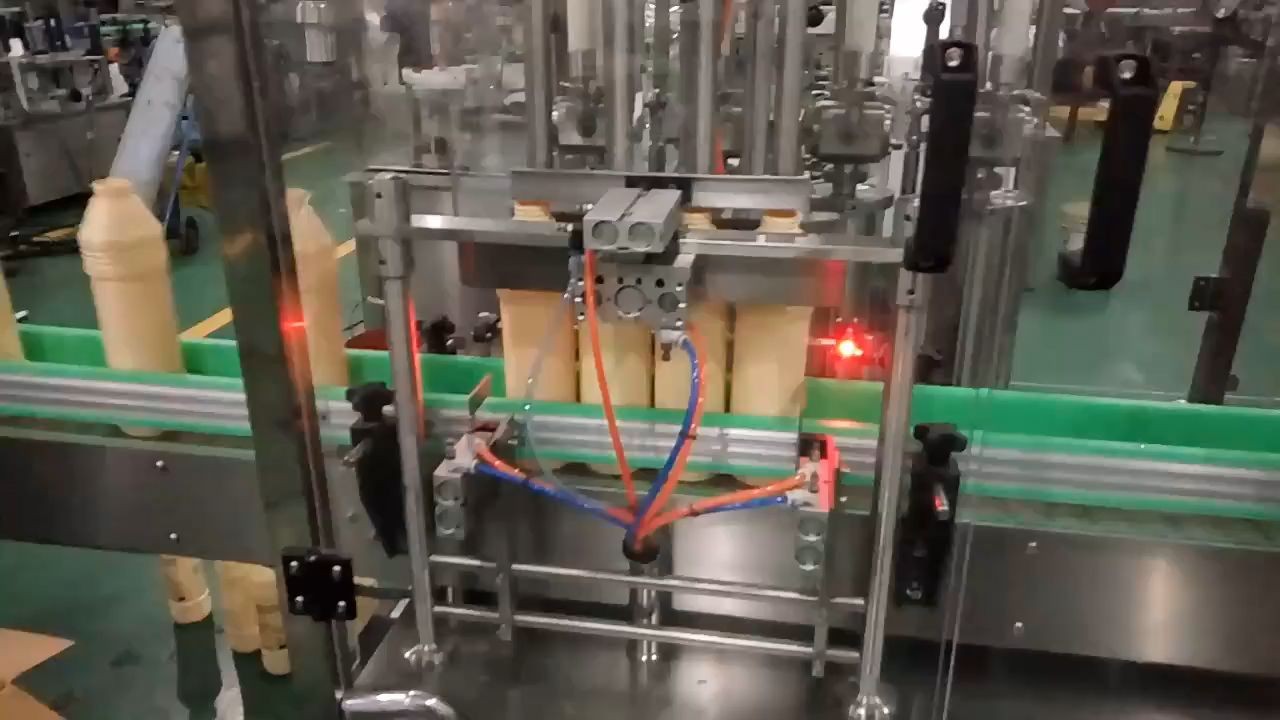

The Automatic Foam Cleanser Overflow Filling Machine is a highly specialized piece of equipment designed to automate the process of filling foam cleanser products. This machine is equipped with advanced technology that ensures precise control over the filling process, resulting in high-quality products with consistent and accurate measurements.

The Automatic Foam Cleanser Overflow Filling Machine typically features a nozzle that dispenses the foam cleanser into the containers, while an overflow mechanism ensures that the product is filled to the desired level. The machine is also equipped with a system for cleaning and sterilizing the filling components, ensuring that the products being dispensed are not contaminated by bacteria or other harmful substances.

One of the key benefits of using the Automatic Foam Cleanser Overflow Filling Machine is the increased efficiency and speed that it provides. This machine can fill foam cleanser products quickly and accurately, reducing the amount of time and labor required to complete these tasks manually. Additionally, the use of an overflow mechanism ensures that the amount of product dispensed is consistent and accurate, reducing the risk of waste or errors.

Another advantage of using the Automatic Foam Cleanser Overflow Filling Machine is the reduction in the risk of contamination. This machine is designed to operate in a clean, sterile environment, ensuring that the products being dispensed are not contaminated by bacteria or other harmful substances.

The Automatic Foam Cleanser Overflow Filling Machine is highly versatile, as it can fill a wide range of foam cleanser products in different sizes and shapes. This machine can be customized to handle a variety of foam cleanser products with different viscosities and densities.

Overall, the Automatic Foam Cleanser Overflow Filling Machine is an essential piece of equipment for any cosmetic manufacturing business looking to streamline their production process and improve the quality and consistency of their products. With its ability to automate the filling of foam cleanser products while maintaining accuracy and consistency, this machine is an invaluable tool for any business in the cosmetic industry.