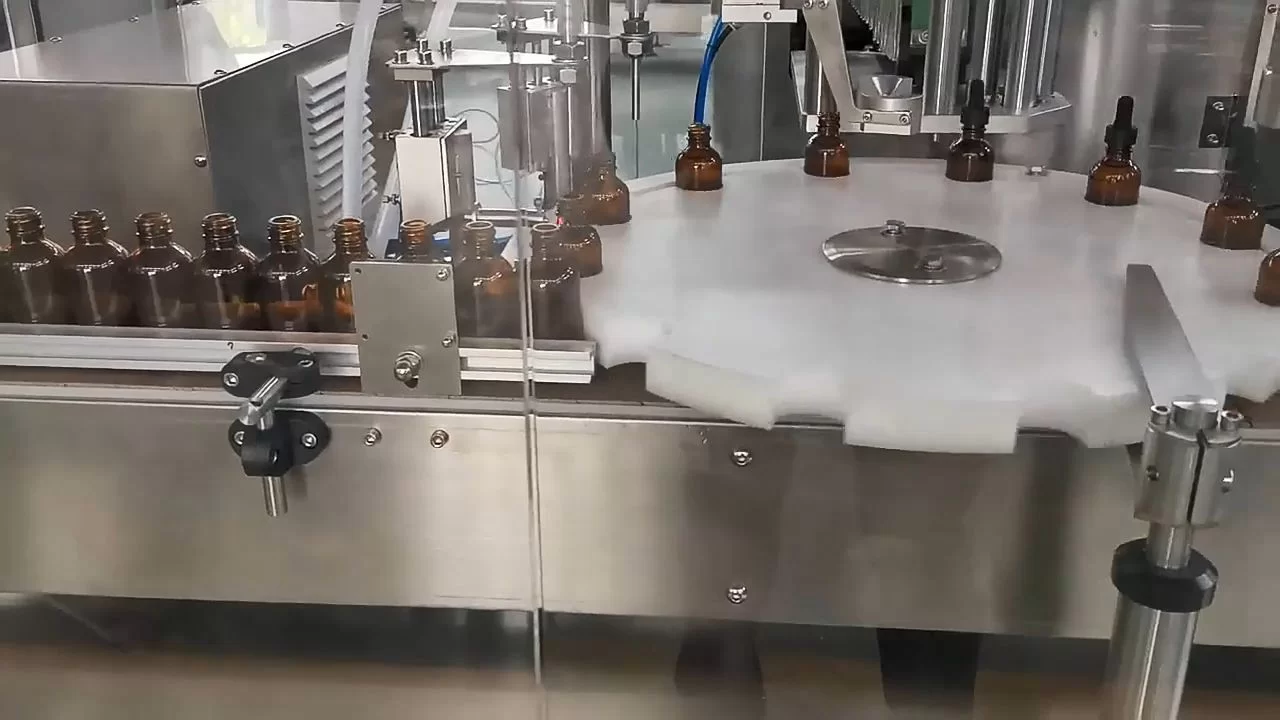

The Automatic Liquid Rotary Cosmetic Cream Filling Capping Machine is a versatile and efficient packaging machine designed to meet the needs of various industries. This machine is ideal for filling and capping liquid and cream-based products, such as lotions, gels, creams, shampoos, and more.

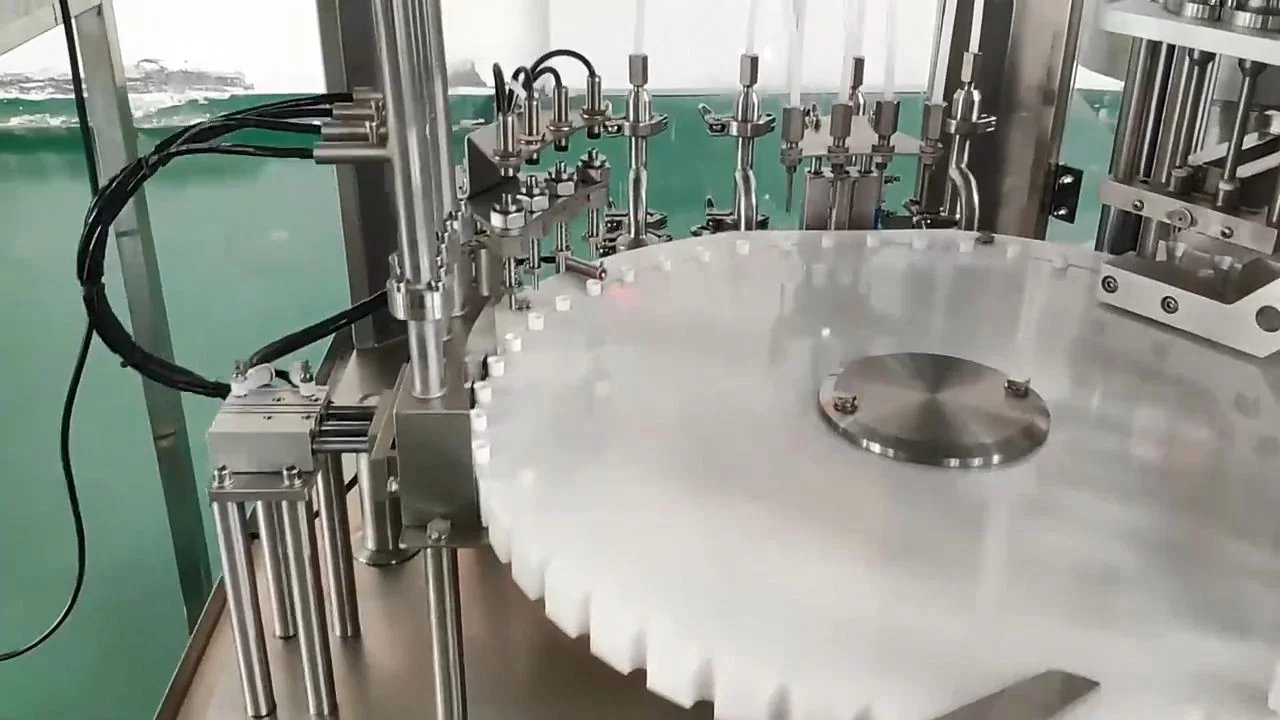

The machine operates by automatically filling the product into containers and sealing them with caps. Its rotary design allows for high-speed production, and its automatic operation reduces labor costs and increases productivity. The machine is equipped with precision filling technology, ensuring accurate and consistent filling volumes for each container. Additionally, the capping system ensures a tight and secure seal, preventing leakage and contamination.

One of the significant advantages of this machine is its flexibility. It can handle a wide range of container sizes and shapes, and it can be easily adjusted to accommodate different product viscosities. The machine is also user-friendly, with a simple and intuitive interface that allows for easy operation and maintenance.

This machine is commonly used in the cosmetic, pharmaceutical, and chemical industries, where high-quality and efficient packaging is essential. With the increasing demand for cosmetic and personal care products, the need for advanced packaging solutions is on the rise. The Automatic Liquid Rotary Cosmetic Cream Filling Capping Machine is an excellent investment for companies looking to improve their production efficiency and enhance their product quality.

In conclusion, the Automatic Liquid Rotary Cosmetic Cream Filling Capping Machine is a reliable and efficient packaging solution that provides precise and consistent filling and capping of liquid and cream-based products. Its high-speed operation, flexibility, and user-friendly interface make it an excellent choice for industries looking to improve their packaging process.

Quick Description

- Condition: New

- Type: Filling Machine

- Machinery Capacity: 4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

- Showroom Location: United Kingdom, Italy, Saudi Arabia, Indonesia, Spain, Thailand, None

- Application: APPAREL, Beverage, Food, Chemical

- Packaging Type: Bags, Barrel, Bottles, Stand-up Pouch, Cartons

- Packaging Material: Glass, Metal, Paper, Plastic, Wood, Small bottle which unable to stand

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V

- Place of Origin: Shanghai, China

- Dimension(L*W*H): 2260*1260*1900

- Weight: 300 KG

- Warranty: 1 Year

- Key Selling Points: High-accuracy

- Filling Material: Milk, Water, Oil, Juice, Powder

- Filling Accuracy: 99

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine

- Name: Nasal spray labeling machine

- Material: SUS 304

- Product advantage: Space saving/Effective cost/Easy operation

- Capacity: 1000-5000bph

- After-sales Service Provided: Engineers available to service machinery overseas

- Bottle type: Tin can/Glass/Plastic bottle

- HS code: 8422 3030 90

- Eligibility rate: ≥99%

More Details

This cans cup bottle labeling machine is suitable for labeling all kinds of regular or irregular containers. It can label double or single label, which is high speed and high precision.This labeling machine, self contained, easy to operate.

Equipped with auto teach programming touch screen. Built in microchip storing different job setting makes fast and easy changeover. This automatic labeling system is ideal for cylindrical container with diameter from 30mm – 100mm. ( size could be customized made) Plastic glass bottle cans cup bottle labeling machine / capping filling machine

You may be warrying those ?

1- How can i fill so many formats my bottles with the machine perfectly withour complex adjusment ?

2- How can i understand your quality ?I do not want any kinds bad machine which failed to live up to my investment .

3- How can i know your machine life ? It looks always beautiful but only in your room .

4- How can i install such a big long machine by myself ? It looks never eaasy at all .

5- How can i recognize the real difference in chinese market ? So many suppliers quoted me every day !!!

6- What can i do if machines get broken in broken ? Who is gona to help me ?

To look how VKPAK boys do

Compared with tradtional machinery , VKPAK smart filler has below characters which are benefited to each customer operation experience :

1- With servo driving , operator just edit the filling parameter on HMI to realize all kinds products packing .

2- 150mm width SS304 protection frame which equied with induction switch is able to stop machine whenever operator open the plexiglass door which is good for human protection .

3- VKPAK machines are all equiped with scale rules for diffeferent kinds bottle replacing , which is convenient for date recording and save the time in adjusting .

4- All VKPAK machine are made of SS304 SS316 which avoiding pollution perfectly , protect custoomer's product quality .

5- Machines are deliveried as whole which solving the stress of after sell installation for customer . VKPAK technicians are standing by all time for on-site service .