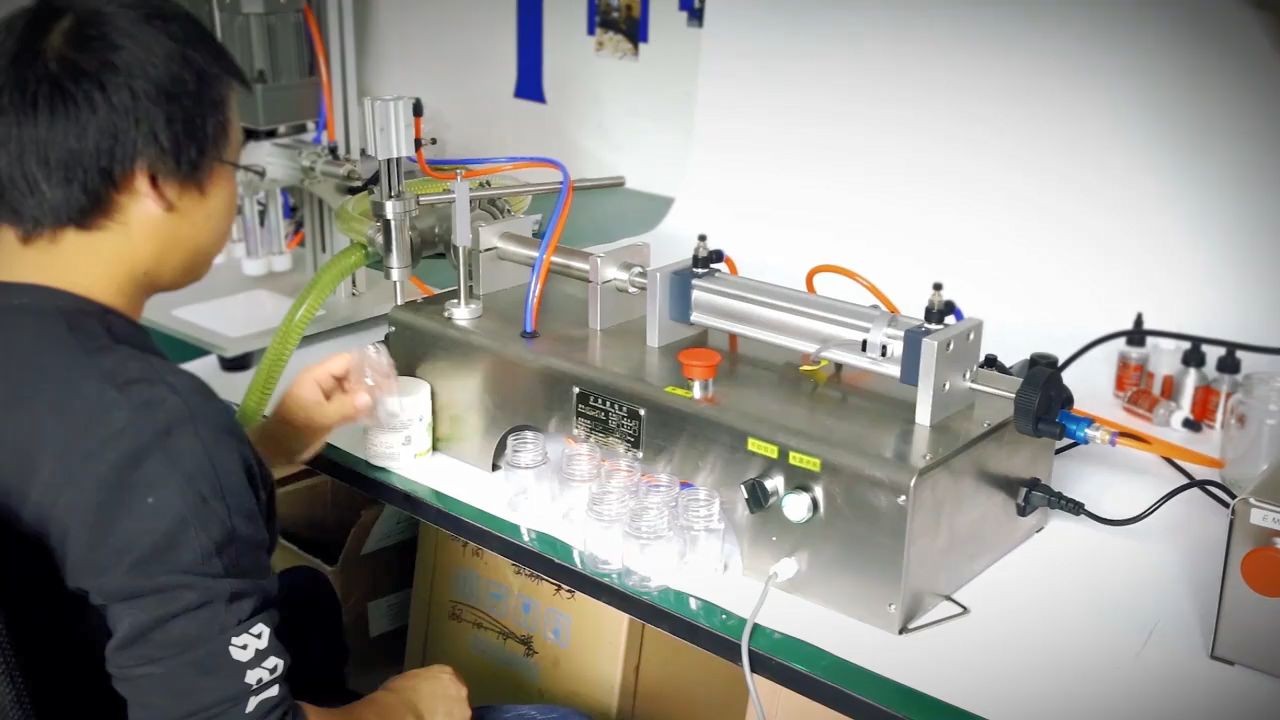

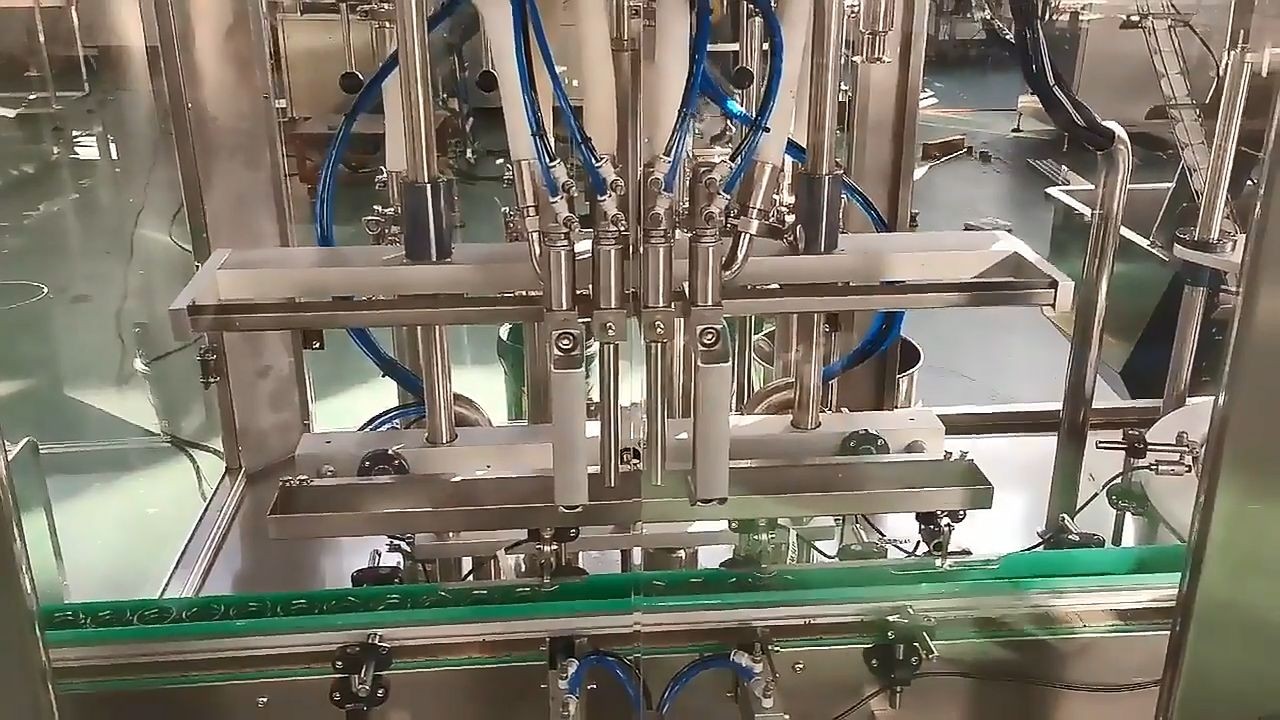

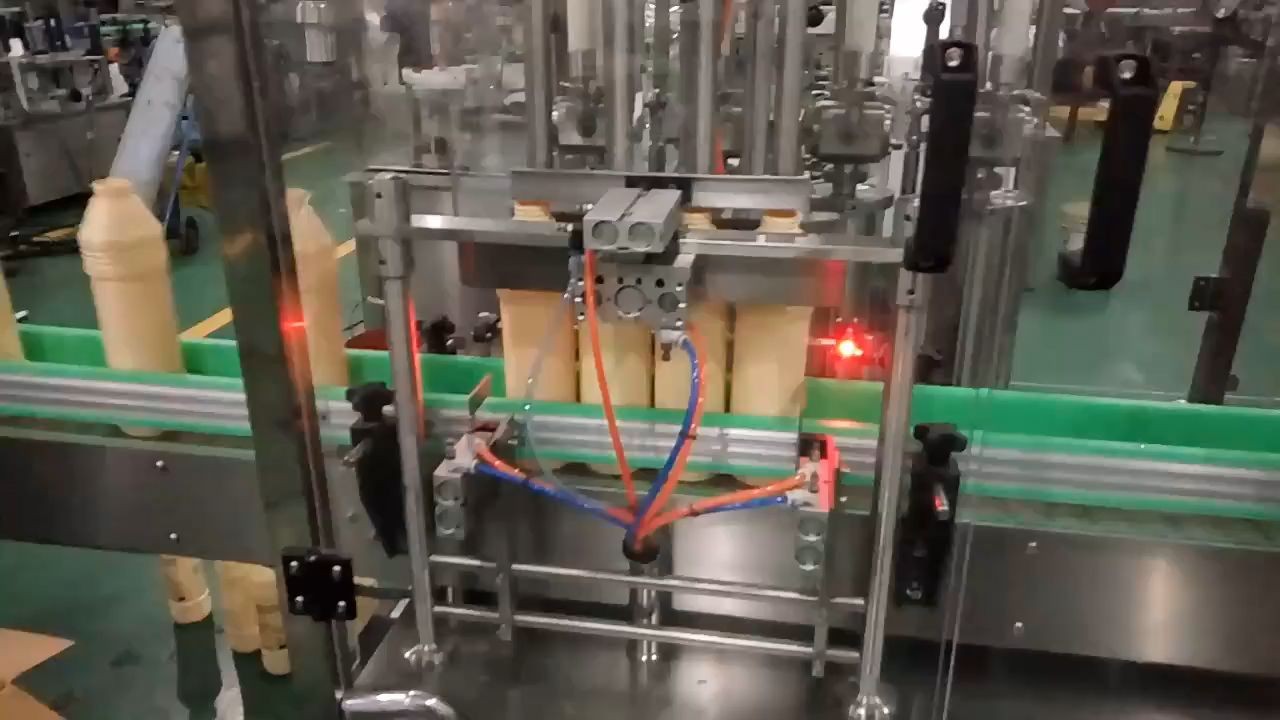

The Automatic Syrup Bottle Filling and Capping Labeling Machine is a highly efficient and advanced packaging equipment widely used in the food and beverage industry. This machine is designed to fill, cap, and label bottles of syrup, juice, or other liquids in a fast and precise manner, reducing labor costs and increasing productivity.

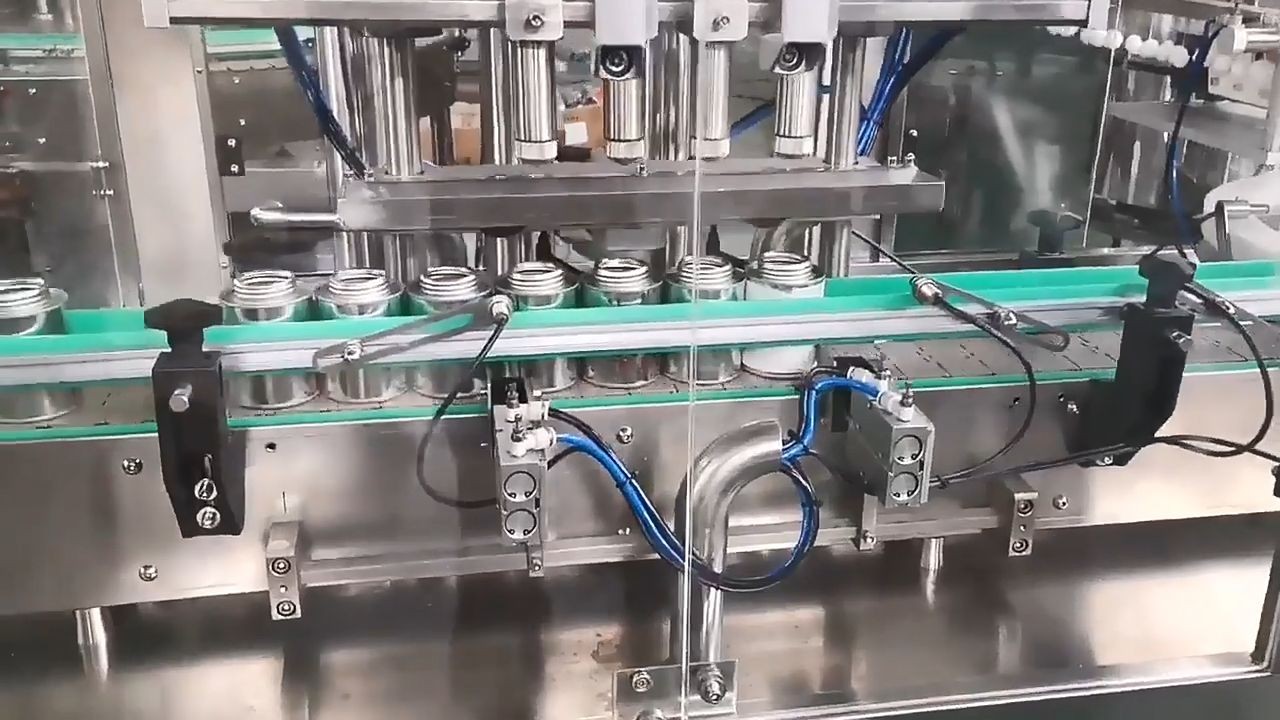

The filling system of the machine is highly accurate and can fill bottles of different sizes and shapes, ensuring that each bottle is filled to the desired level with minimal wastage. The capping system is designed to handle different types of caps, including screw caps, press caps, and more, making it highly versatile. The labeling system uses advanced technology to apply labels with high accuracy and consistency, ensuring that each bottle is correctly labeled.

The Automatic Syrup Bottle Filling and Capping Labeling Machine has several advantages. It is highly efficient and can fill and cap up to 150 bottles per minute, making it ideal for high-volume production lines. The machine is also easy to operate, with a user-friendly interface that allows operators to control the various settings and monitor the production process. Additionally, it is designed to meet strict hygiene and safety standards, making it suitable for use in the food and beverage industry.

The machine's characteristics include a stainless steel construction that is durable and easy to clean, a PLC control system that ensures precise control and accurate filling, and a variable frequency drive that allows for easy adjustment of the filling speed. The machine is also equipped with a detection system that detects missing caps and bottles, reducing waste and increasing efficiency.

The Automatic Syrup Bottle Filling and Capping Labeling Machine is widely used in the food and beverage industry, especially for filling and packaging syrup, juice, honey, and other liquid products. With the increasing demand for convenience and ready-to-drink products, the market for this machine is expected to grow steadily in the coming years. The machine is also suitable for use in other industries, such as cosmetics and pharmaceuticals, where accurate filling, capping, and labeling are essential.

Quick Description

- Type: Filling And Capping Machine

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Showroom Location: Egypt, Turkey, United States, Italy, France, Germany, Philippines, Russia, Spain, Thailand, Morocco, Argentina, Algeria, Sri Lanka, Bangladesh, Kazakhstan, Uzbekistan, Tajikistan

- Application: Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, APPAREL, Textiles

- Packaging Type: Bottles

- Packaging Material: Plastic, Paper, Glass

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 220V

- Place of Origin: China

- Dimension(L*W*H): 1300*700*1200mm

- Weight: 210 KG

- Warranty: 1 Year

- Key Selling Points: High-accuracy

- Machinery Capacity: 20-100

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: PLC, Pressure vessel, Gear, Motor, Engine, Bearing, Gearbox

- Product name: Wrap-round labeling machine

- After-sales Service Provided: Online Video Technical Support

- Labeling speed: 40-120pcs/min

- Keyword: Labeling

- Labeling type: Wrap round

- Bottle type: Plastic /glass/Pet

- Label material: Sticker/paper

- Function: Label application

- Service: Online technicians support

- Drive mode: Servo system

More Details

Product Description

VKPAK is a professional manufacturer of filling line for over 10 years, customized filling lines for different industry customers like food and beverage, cosmetic, medical industry, chemical industry and etc, lots of successful cases for your reference. The full automatic liquid filling machine is designed for saving time on adjusting and testing machine, it can fill liquid or paste accurately by entering a certain filling volume. The PLC control method makes it easy to operate and thigh speed working efficiency is ideal for different scale production. It can work with the automatic capping machine and labeling machine and other equipment based on customer requirement. VKPAK filling line is widely used in the following industries:

* Beverage Filling Machine Line (such as water, juice, beer, liquor, vodka, wine etc.)

* Food Filling Machine Line (such as honey, sauce, oil, chocolate, vinegar etc. )

* Chemical and Pharmaceutical Filling Machine Line (such as syrup, eye drop, alcohol, reagent, ampoul, syringe etc. )

* Cosmetics Filling Machine Line (such as perfume, body spray, nail polish, cream, lotion, detergent, hand gel etc. )

• Suitable for gallon containers

• More container shapes

• Taller and wider containers

• 360 degree touch screen

• Self teaching sensors

• Enclosed slide out controls

• Over 13% more energy efficient

• Range of label size 6 - 170mm (1/4 - 6.7”) (H) 6 - 300mm (1/4 - 11.8”) (W)

• Range of container width 6.5mm - 165mm (0.26” - 6.5”)

• Range of container height 6.5 - 305mm (0.26 - 12”)

• Conveyor width 152mm (6.5”)

• Power source 110/220 v 50/60 Hz 1 PH

• Power consumption 0.660 kW

• Label dispensing speed 40m/min (131.2’/min)

• Conveyor speed 22m/min (72.2’/min)

• Label spool diameter 356mm (14”)

• Label spool inner core 76mm (3”)

• Drive motor Stepper

• PLC Panasonic

• Dimensions (L-W-H) 2,420 x 1,380 x 1,350mm 95.3” x 54.3” x 53.1”

| FEATURES | BENEFITS |

| Flexible label head tilts on x-y axis | Great for round, tapered or shaped containers |

| Manual Adjustments | |

| Adjustable applicator height | Suitable for a wide variety of containers and labels |

| Adjustable conveyor height | Easy to adapt to any existing packaging line |

| Manual position setting | Easy to use adjustments ensure labels are placed accurately on the container |

| Touch Screen Controls | |

| 5.5” color LCD touch screen controls | Easier operation of controls |

| Touch screen rotates 360 degrees | Allows the machine to be controlled from any position |

| Stores up to 30 product settings | Faster and more accurate setup |

| Built-in operating instructions | Enables quick setup and easy changeover |

| Easy to follow fault instructions | Enables operator to quickly identify and fix problems |

| Screensaver | Reduces the risk of screen burn |

| Data storage for maintenance and usage | Simplifies scheduling of maintenance activities |

| Built-in printer controls | Allows for ‘plug & play’ future printer upgrades |

| FEATURES | BENEFITS |

| Sensor Features | |

| Production pre-set - stop function | Automatically stops once the pre-set quantity has been met |

| Missing label auto stop system | Ensures all products are labeled |

| Label countdown | Allows operator to monitor run progress |

| Batch counter | Easy to keep track of batches |

| Label counter | Simplifies regulatory tracking of labels |

| Container/production run counter | Provides total production quantity |

| Label position set | Ensures labels are placed correctly on product |

| One touch label sensor | Allows operator to use “one touch” feature on sensor to “teach” the sensor the label characteristics |

| Auto label sensor set | Detects labels and setup machine automatically from touch screen |

| Auto label length set | Detect label lengths and setsup machine automatically from touch screen |

| Design and Construction | |

| Adjustable to 8 speeds | Easily adjusts to line speeds |

| Battery free microprocessor | Maintains default settings and memory even after sitting idle for long periods |

| Slide-out controls and electronics stored in lower cabinet | Enables quick and easy servicing |

| Manufactured with stainless steel and anodized aluminum | Robust, long lasting construction with quick and easy cleanup |

| Manufactured to strict ISO 9001 standards | High quality, consistent manufacturing ensures easy repairs and/or upgrades |

| GMP compliant | Designed to easily surpass standards of compliance auditors |

| Fully synchronized controls | Ensures all components run at the proper speed |

| Stepper driven motor | Fine adjustment allows precise label placement |

The unscrambler which made of SS304 is used to arrange and input bottles for label application , operator only put bottles on table . Drived by gear motor, positive and negative rotation

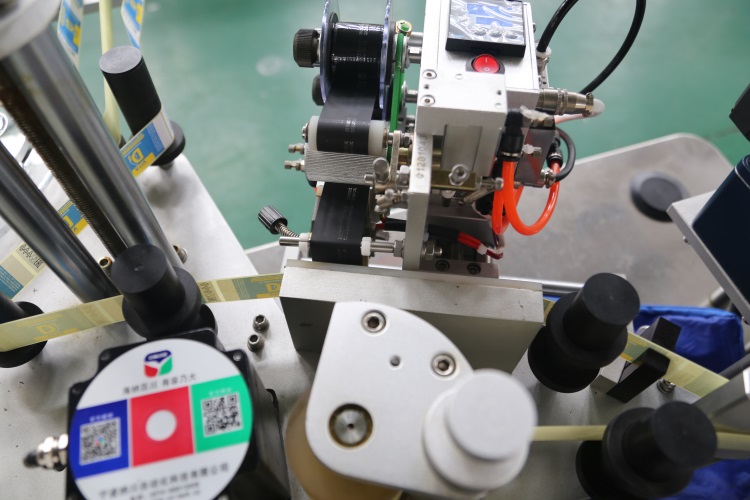

Servo driving system

Servo is always running better than normal , PX-BL120 label drived by servo motor ,make the label to be released more fluently ,without broken or cutting circumstance happening

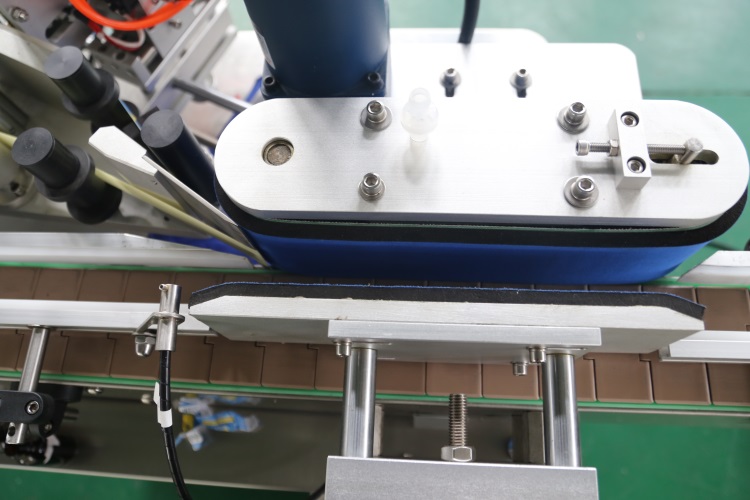

Labeling belt

Wrap round label aplicator, Positive &negative we use as we use the sponge sponge as compressive belt, sponge has very strong contractility, which means that the label will be tightly squeezed without damage, the same applies to wide bottle caps, small diameter bottle samples, each tag can be perfectly applied the bottle and there will be no crease for extrusion, sponge has very strong contractibility, This means labels are tightly squeezed without breaking. This also applies to samples with wide caps and small bottle diameters, where each label fits perfectly without wrinkling

Height-width-Angle adjustment

Any labeling machines are all suitable for different formats ,which means sone kind of adjustments are necessary ,height ,angle , width , these 3 aspects decide how to put label in right way .

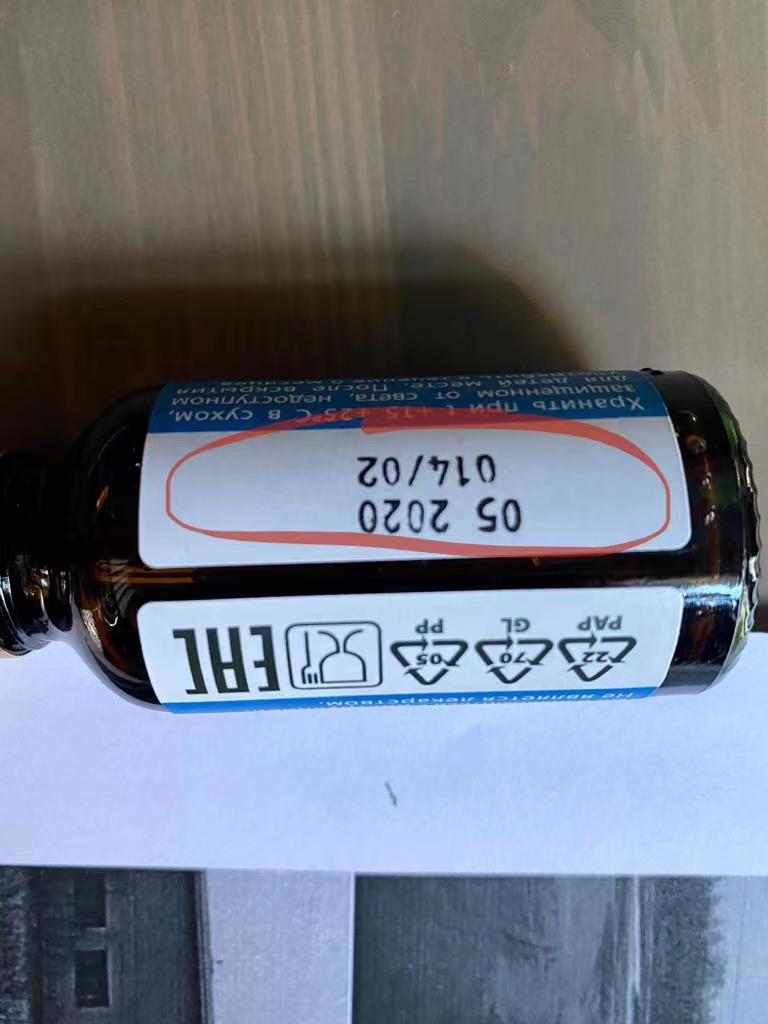

Printing engine

We set thermal printer with the labeler itself , to coding number , production date with the label