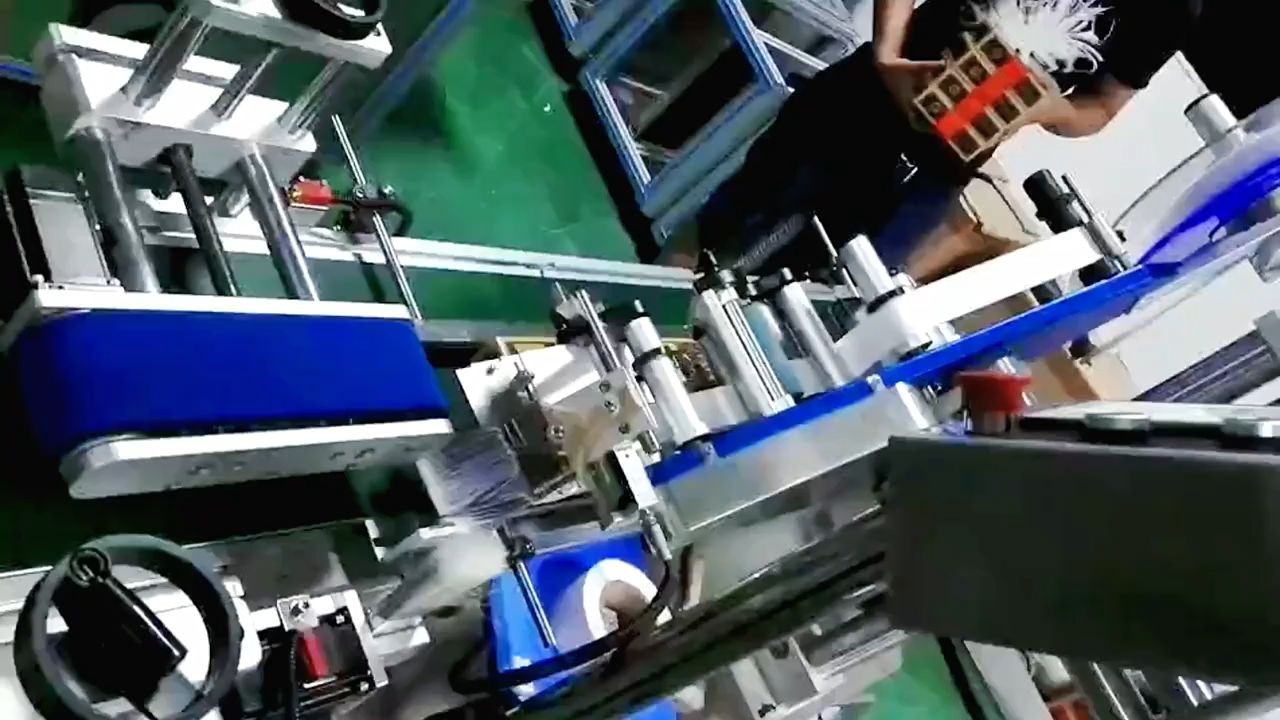

Cold Wet Glue Labeling Machine for Round Bottles

1. Based on screw bottle entering bottles moving are steadier.

2. Label box can be controlled to satisfy different labeling request.

3. The size of label box can be changed according to the different label size. The operation is convenient and easy.

4. It uses the glue pump and the glue can be used circularly. Quantity of flowing glue also can be changed to satisfy different labeling request.

5. Compare to self adhesive labels, Paper label make a low cost.

| Model | Automatic Wet Glue Labeling Machine |

| Drive | Shift motor driven |

| labeling speed | 50-120pcs/min |

| bottle height | 60-450mm |

| bottle diameter | 55-110mm |

| power | AC 220V/380V 50/60HZ 750W |

High speed automatic wet glue labeling machines are an efficient and cost-effective way to maximize efficiency in the labeling process. These machines provide precise, accurate labeling at speeds of up to 120 labels per minute, making them ideal for businesses looking to streamline their production line. With advanced features such as servo motors, touch screen controls, and automatic label dispensing systems, these machines are designed to increase productivity while reducing costs. They also come with a variety of options such as label detection sensors and vision systems for improved accuracy and quality control. With their ability to handle a wide range of container sizes and shapes, these high speed automatic wet glue labeling machines are perfect for any business looking to improve efficiency in their labeling process.

Benefits of High Speed Automatic Wet Glue Labeling Machines for Increased Efficiency

High speed automatic wet glue labeling machines are an efficient and cost-effective solution for labeling products. These machines offer a number of benefits that make them an ideal choice for businesses looking to increase their efficiency.

One of the main advantages of high speed automatic wet glue labeling machines is their ability to quickly and accurately apply labels to products. The machine's advanced technology allows it to apply labels at speeds up to 120 bottles per minute, making it much faster than manual labeling methods. This increased speed can significantly reduce the amount of time required for labeling, resulting in improved productivity and cost savings.

In addition, these machines provide greater accuracy than manual methods. The machine's sensors detect when a label is applied correctly, ensuring that each product is labeled correctly and consistently every time. This helps reduce errors and ensures that customers receive properly labeled products each time they purchase from your business.

Finally, high speed automatic wet glue labeling machines are easy to use and maintain, making them a great choice for businesses with limited resources or personnel who may not have the experience or expertise necessary for manual labeling processes. With minimal training required, operators can quickly become proficient in using these machines so they can get up and running quickly without having to invest in additional staff or resources.

Overall, high speed automatic wet glue labeling machines offer businesses numerous benefits including increased efficiency, accuracy, cost savings and ease of use that make them an ideal choice for any business looking to improve its production process.

Understanding the Design and Operation of Wet Glue Labeling Machines

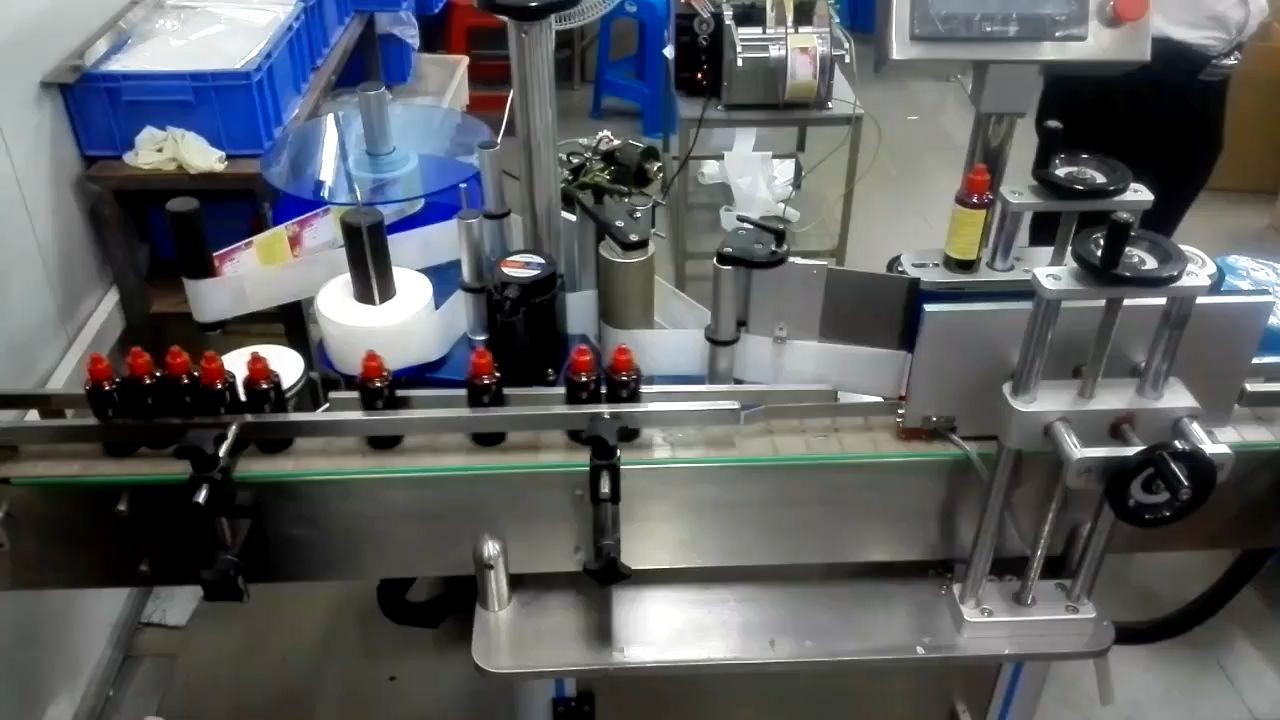

Wet glue labeling machines are a type of labeling machine that uses a wet adhesive to attach labels to products. This type of labeling machine is commonly used in the food and beverage industry, as well as in the pharmaceutical and cosmetics industries. The design and operation of wet glue labeling machines is relatively simple, yet highly efficient.

The main components of a wet glue labeling machine include an applicator head, an adhesive reservoir, and a conveyor system. The applicator head applies the adhesive to the product surface using either pressure or vacuum-based technology. The adhesive reservoir holds the wet glue which is then fed into the applicator head for application onto the product surface. Finally, a conveyor system transports products through the labeler at a predetermined speed while ensuring that each product receives an accurate amount of adhesive applied in exactly the right place on its surface.

The operation of these machines begins with loading products onto its conveyor belt for transport through it. As each product passes under or over the applicator head, it receives an accurate amount of adhesive which is then allowed to dry before moving on to be packaged or stored for later use. Depending on their size and design, some wet glue labelers may also include additional features such as print registration systems or vision inspection systems which help ensure accuracy during production runs.

Overall, understanding how wet glue labeling machines work can help manufacturers increase their production efficiency while also improving quality control processes within their operations. With careful maintenance and proper use, these machines can provide reliable performance over long periods of time without requiring frequent repairs or replacements due to wear-and-tear issues caused by regular use over time

Optimizing Performance with Automated Quality Control Features

Automated Quality Control (AQC) features are an essential part of optimizing performance in any organization. AQC features provide a way to automate the process of quality control, ensuring that all processes and procedures are being followed and that the highest standards of quality are maintained. This can help to reduce errors, improve efficiency, and ensure customer satisfaction.

AQC features can be used to monitor different aspects of a process or procedure, such as accuracy, consistency, speed, and safety. For example, AQC can be used to monitor the accuracy of data entry into a system or the consistency of product assembly on an assembly line. By monitoring these factors regularly with automated tools, organizations can quickly identify any areas where improvements need to be made in order to optimize performance.

In addition to monitoring existing processes and procedures for optimization purposes, AQC features can also be used for predictive analytics purposes. Predictive analytics allow organizations to anticipate potential problems before they occur by analyzing historical data and identifying patterns that may indicate future issues or areas where improvements could be made. This helps organizations stay ahead of potential problems before they arise so that they can take corrective action as needed in order to optimize performance levels across their organization.

Overall, Automated Quality Control (AQC) is an important tool for optimizing performance in any organization by helping them maintain high standards of quality while also staying ahead of potential issues through predictive analytics capabilities.

Troubleshooting Common Issues with High Speed Automatic Wet Glue Labeling Machines

Troubleshooting common issues with high speed automatic wet glue labeling machines can be a complex process. It is important to understand the machine's components and how they interact with each other in order to properly diagnose and repair any problems that may arise. Common issues include incorrect label placement, adhesive not sticking, or labels not being applied correctly.

The first step in troubleshooting these issues is to inspect the machine for any visible damage or worn parts that could be causing the problem. If any parts are found to be damaged or worn, they should be replaced immediately. Additionally, all of the machine’s settings should be checked and adjusted as necessary to ensure proper operation. This includes verifying that the correct label size is being used and that all sensors are functioning properly.

Next, it is important to check for blockages in the system which could prevent labels from being applied correctly or cause adhesive not sticking properly. This can include checking for debris build-up around nozzles and cleaning out any clogged tubes or hoses connected to the system if necessary.

Finally, it is important to test run a few labels through the machine after making adjustments in order to verify that everything is working correctly before continuing production runs on a large scale basis. By following these steps carefully, most common issues with high speed automatic wet glue labeling machines can easily be identified and corrected quickly so production runs can continue without interruption.

Integrating Automated Labeling Systems into Existing Production Lines

Integrating automated labeling systems into existing production lines can be a cost-effective way to increase efficiency and accuracy. Automated labeling systems use advanced technology to accurately identify, sort, and label with minimal human intervention. This significantly reduce labor costs while increasing the speed of production. Additionally, automated labeling systems are designed to integrate seamlessly with existing equipment and software, allowing for a smooth transition from manual processes to automated ones. Furthermore, these systems provide greater accuracy than manual methods due to their ability to detect errors in labels before they are applied. This ensures that all products are labeled correctly and efficiently. With the right system in place, businesses can benefit from increased productivity while reducing costs associated with labor and mistakes caused by manual processes.

Conclusion

High speed automatic wet glue labeling machines are an excellent way to maximize efficiency in any size business. They provide fast and accurate labeling of products, allowing businesses to quickly and accurately label their products for sale. The high speed and accuracy of these machines also reduce the amount of time needed for product labeling, resulting in a more efficient production process. Additionally, the use of wet glue labels allows businesses to create custom labels that are more resistant to damage from water or other liquids, providing a longer lasting label that is better suited for a variety of applications. With the use of high speed automatic wet glue labeling machines, businesses can maximize their efficiency while still providing quality product labels.