Quick Description

- Type: Multi-Function Packaging Machine

- Production Capacity: 20bag/min, 25bag/min, 50bag/min

- Applicable Industries: Garment Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Printing Shops, Food & Beverage Shops

- Weight (KG): 700

- Showroom Location: Egypt, Philippines

- Condition: New

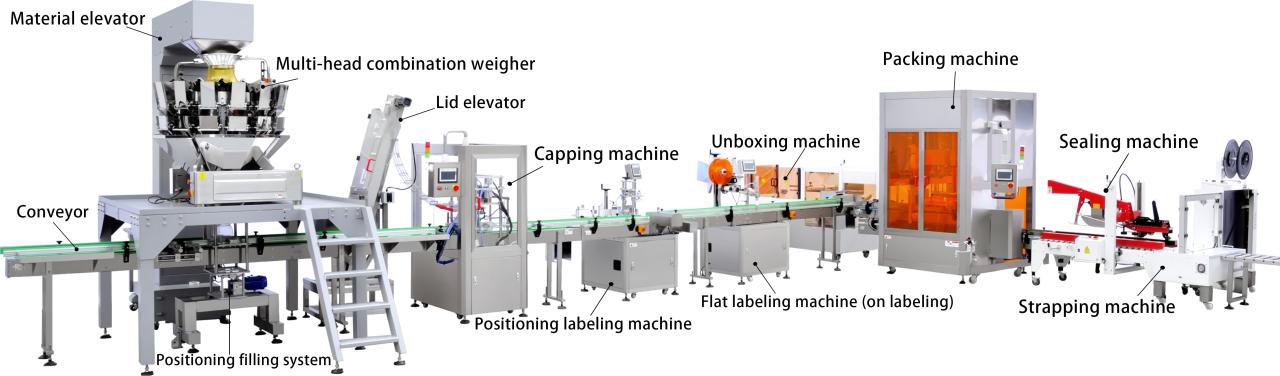

- Function: FILLING, Wrapping, Labeling, Capping, Sealing, customizable

- Application: Food, Beverage, Medical, Chemical

- Packaging Type: CANS, Bottles, Bags

- Packaging Material: Plastic, Metal, Glass

- Automatic Grade: Automatic

- Driven Type: Electric

- Voltage: 380V

- Dimension(L*W*H): Customized size

- Warranty: 1 Year

- Key Selling Points: Long Service Life

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Pressure vessel, PLC, Bearing, Engine

- Product name: Grain powder packaging machine

- Number of filling heads: Can be customized

- Filling capacity: 100-1000ml, 500-5000ml, 1-10L

- Filling form: Multi-headed into the bottom of the bottle filling

- Filling speed: 20-50 bottles/minute

- Filling accuracy: ±1%

- Air pressure: 0.6-0.8MPa

- Power: 4KW/380V three-phase five-wire

- Main trough capacity: 200 liters

- Material: Material Elevator

More Details

| Technical Parameter | |

| 10 head multi-head wigher particle filling machine | |

| Single weighing range | 10-1000g |

| Maximum weight | 6500g |

| Average error of single bottle | 0.2-0.7g |

| Weighing accuracy range | 0.1-0.5g |

| Maximum weighing speed | 25 bottles / min (1000g / bottle) |

| Hopper capacity | 1600ml |

| The hopper is in the form of double row memoryless bucket, and the driving mode is stepping motor | |

| Chuck vibration multihead weigher filling machine | |

| Suitable product | bottle or bag, provided by the customer |

| Filling capacity | 450g, 1000g, 2000g (for example) |

| Filling form | multi-head weigher filling |

| Number of nitrogen charging heads | 1 head |

| Production speed | 25 bottles / min (1000g / bottle) |

| Overall power | 1.8kw |

| Program control | PLC touch screen man-machine interface |

| Power supply | AC220V, 60Hz, single phase |

| Materials of filling nozzle and other parts in contact with materials: 316 stainless steel | |

Chuck vibration multihead weigher filling machine

Details Images

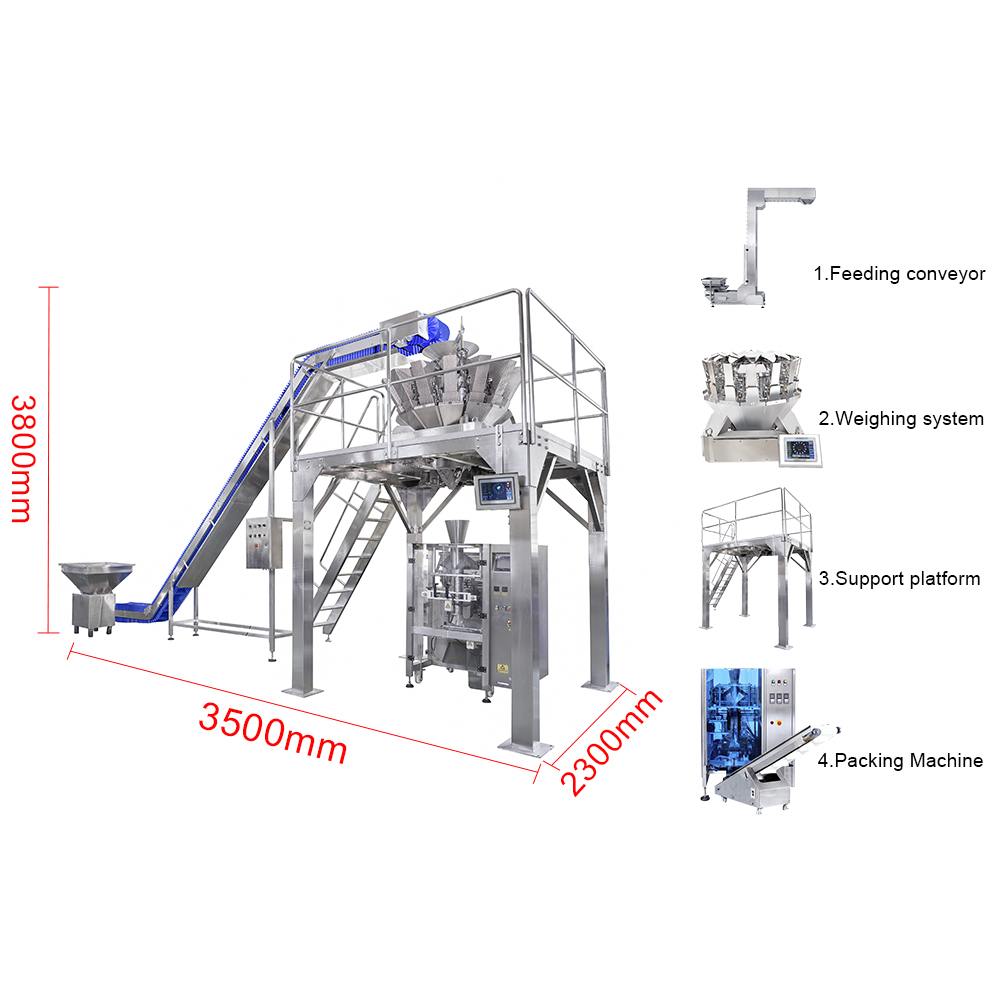

The Nut Snack Food Multihead Weigher Weighing Packing Machine is an automated packaging solution designed for the accurate and efficient weighing and packing of various nut and snack food products. This machine utilizes multihead weigher technology, which enables it to weigh multiple product portions at the same time, increasing the speed and efficiency of the packaging process.

The machine consists of a product feeding system, multihead weighers, a bag-making system, and a vertical packing machine. The product feeding system feeds the nuts or snacks into the multihead weighers, which accurately weigh the desired portions of product. The bag-making system then creates bags of the appropriate size and shape, which are filled with the weighed product portions by the vertical packing machine. The filled bags are then sealed and ready for distribution.

This packaging machine is highly versatile and can handle a wide range of nut and snack food products, including almonds, cashews, peanuts, pistachios, popcorn, chips, and more. The multihead weighers ensure that each bag is filled with the correct amount of product, while the bag-making system and vertical packing machine create high-quality packaging that is suitable for retail sale.

The Nut Snack Food Multihead Weigher Weighing Packing Machine is ideal for manufacturers and distributors of nut and snack food products who need to package their products quickly and efficiently. With its high speed and accuracy, this machine can help businesses increase their production capacity while minimizing waste and improving product quality.