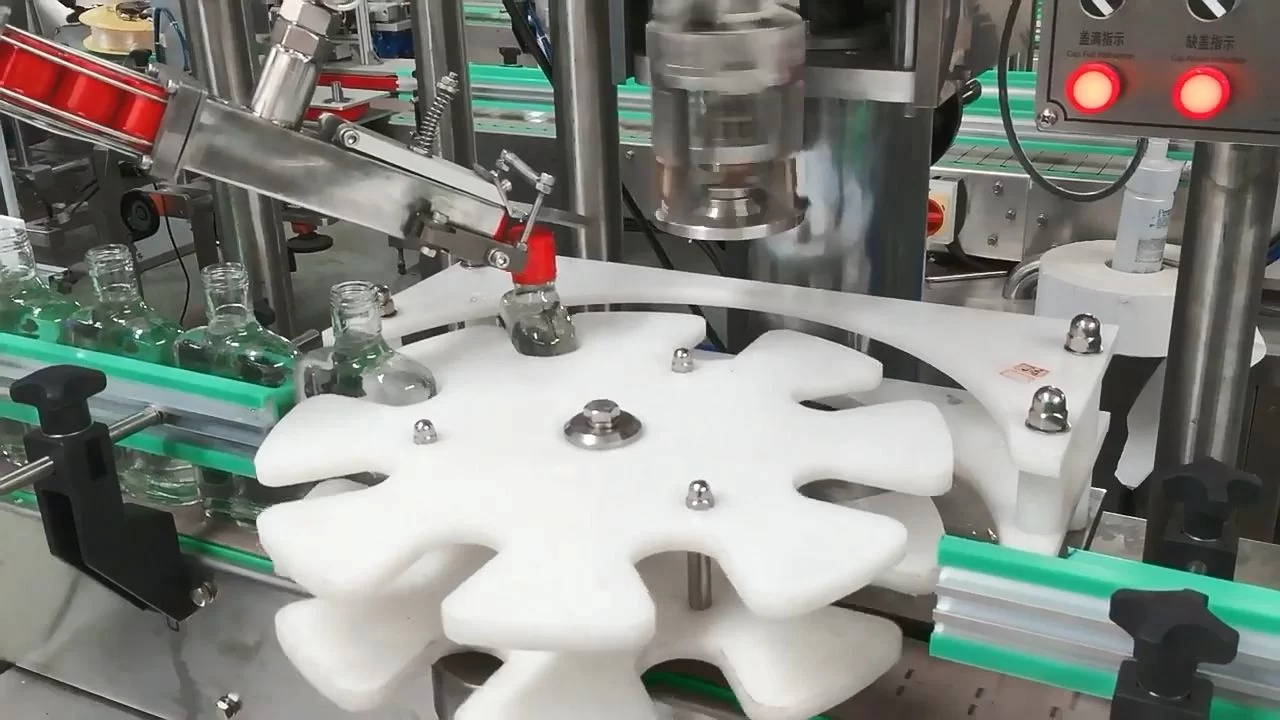

The automatic spindle screw capping machine is extremely flexible, is capable of capping accurately and rapidly any cap, such as trigger cap, metal cap, flip cap and so on.

MAIN FEATURE

1. Variable speed AC motors.

2. Spindle wheels adjustment knobs, with lock nut hand wheel.

3. Meter Index for easy mechanical adjustment.

4. No change parts required for a wide range of containers

5. Comprehensive universal cap chute and escapement

6. With 2 layer bottle clamping belt, suitable for containers of various shap.

| 1 | Name/Model | Automatic linear spindle capping machine | |

| 2 | Capacity | 40-150 bottle/minute (actual capacity depends on bottle and caps | |

| 3 | Cap diameter | 20-120mm | |

| 4 | Bottle Height | 40-460mm | |

| 5 | Dimension | 1060*896*1620mm | |

| 5 | Voltage | AC 220V 50/60HZ | |

| 6 | Power | 1600W | |

| 7 | Weight | 500KG | |

| 8 | Cap feeding system | Elevator Feeder | Vibration cap sorter |

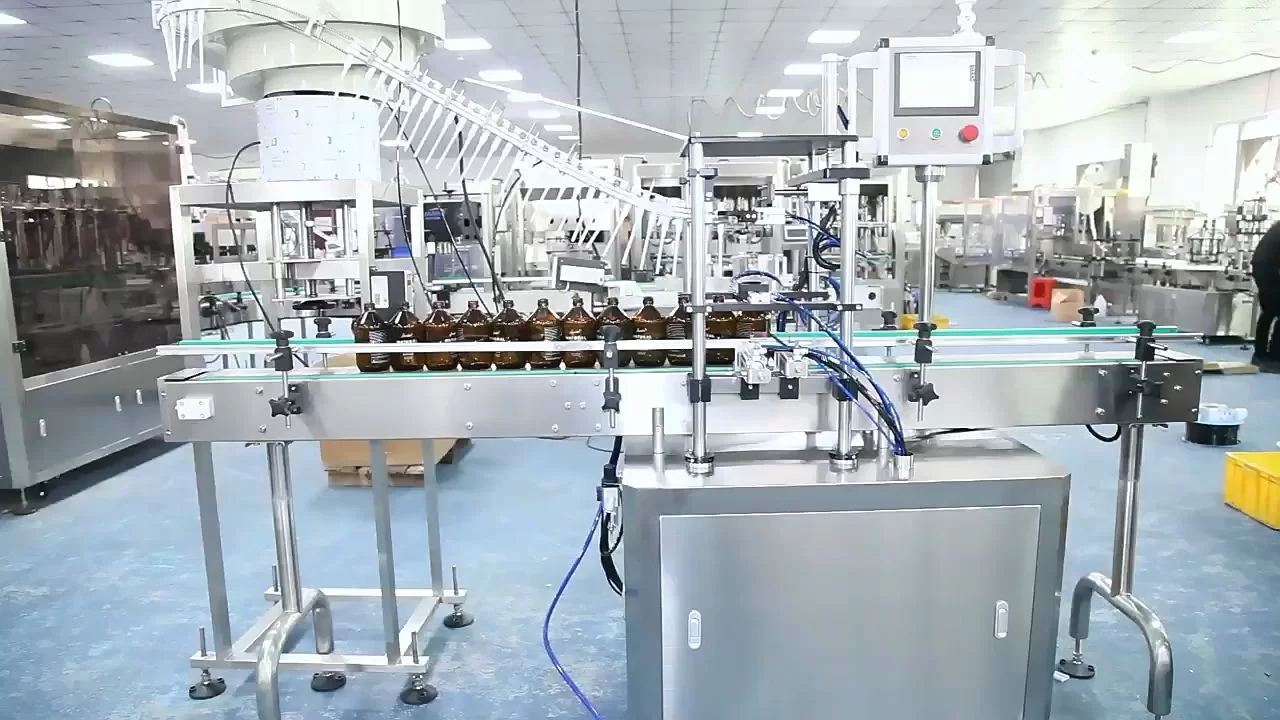

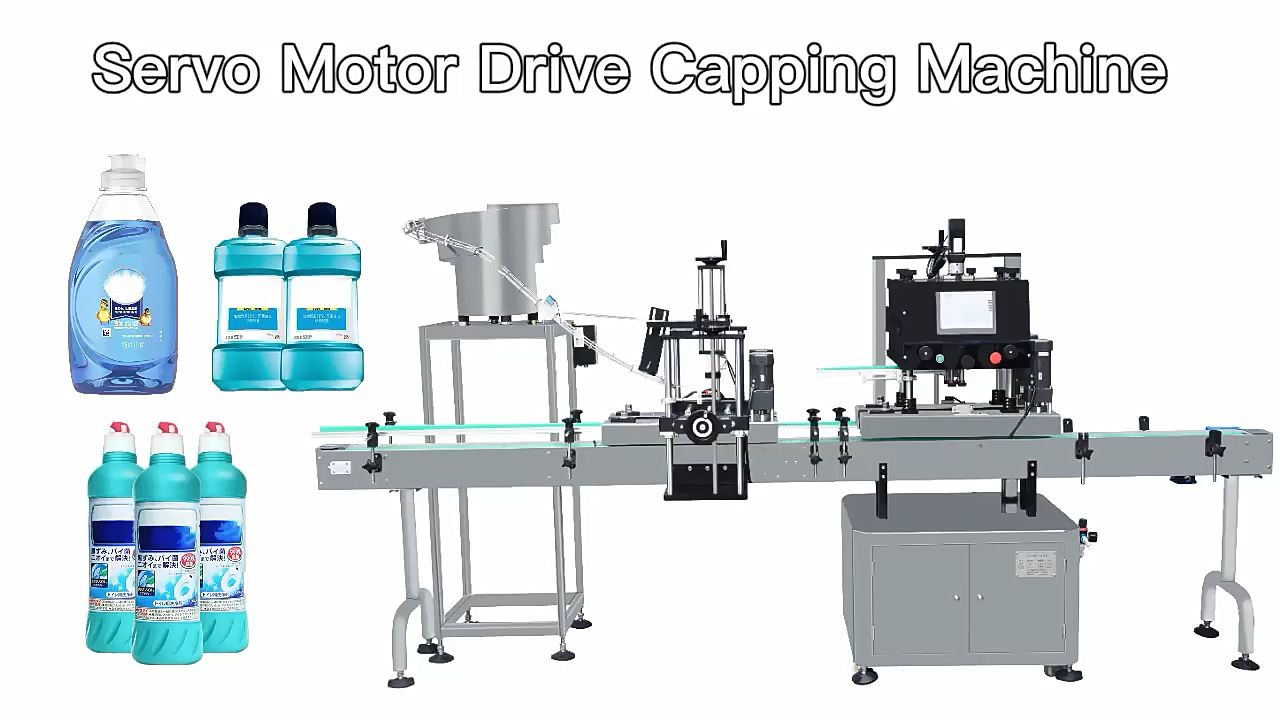

An automatic linear detergent liquid soap pump bottle capping machine is a type of industrial equipment that is designed to automatically cap pump bottles of liquid soap and detergent. This machine is commonly used in the personal care and household cleaning industry, specifically in the production of liquid soap and detergent products.

The machine works by feeding the bottles onto a conveyor belt, which then moves them through the capping station. The capping station uses a capping head to tighten and secure the pump caps onto the bottles, ensuring a tight seal that prevents leakage.

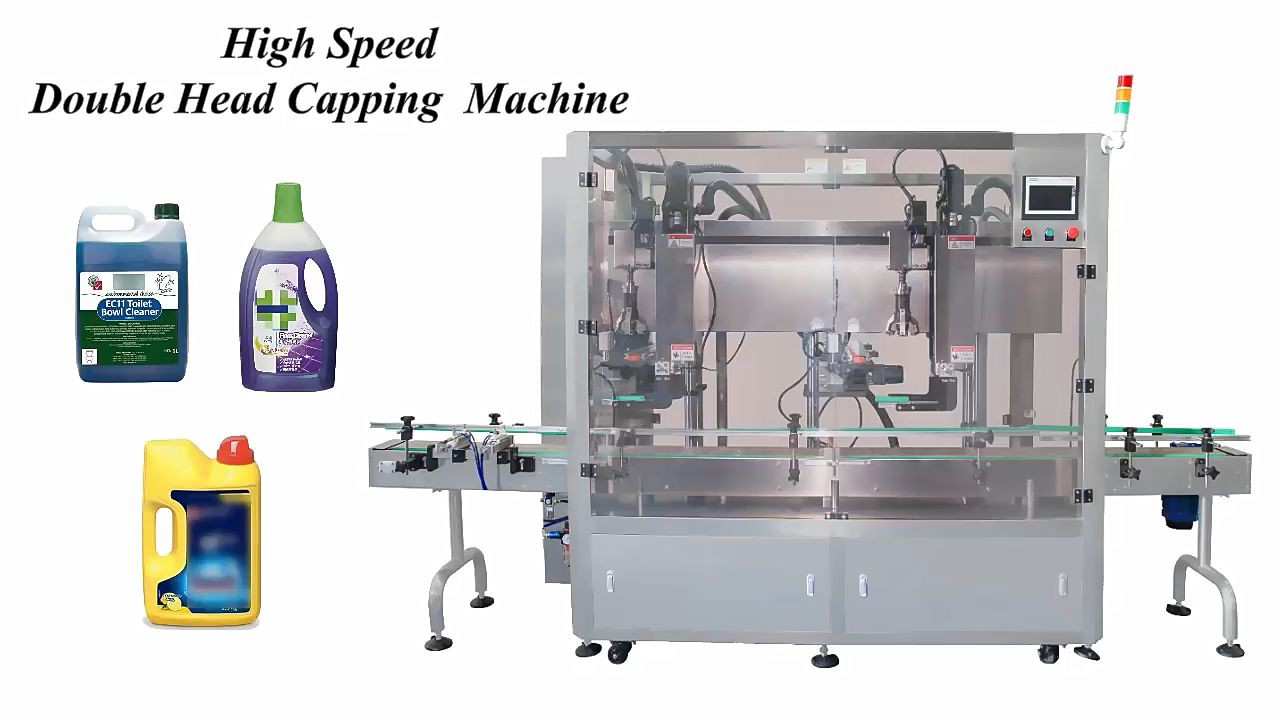

One of the key advantages of the automatic linear detergent liquid soap pump bottle capping machine is its high speed and efficiency. With the ability to cap up to 200 bottles per minute, this machine significantly increases production efficiency, reduces labor costs, and improves overall product quality.

Another advantage of this machine is its versatility. It can handle a wide range of bottle sizes and shapes, thanks to its adjustable conveyor and capping head. The machine's flexibility also allows for easy switching between different types of pump caps, minimizing downtime and maximizing productivity.

Additionally, the machine is equipped with a user-friendly touch screen interface that makes it easy to control and monitor the capping process. The interface allows operators to adjust the capping speed, conveyor speed, and other settings, ensuring optimal performance and efficiency.

Overall, an automatic linear detergent liquid soap pump bottle capping machine is an essential piece of equipment for any company that needs to cap large quantities of liquid soap and detergent bottles. Its speed, efficiency, accuracy, versatility, and ease of use make it an ideal solution for improving production efficiency and quality in the personal care and household cleaning industry.