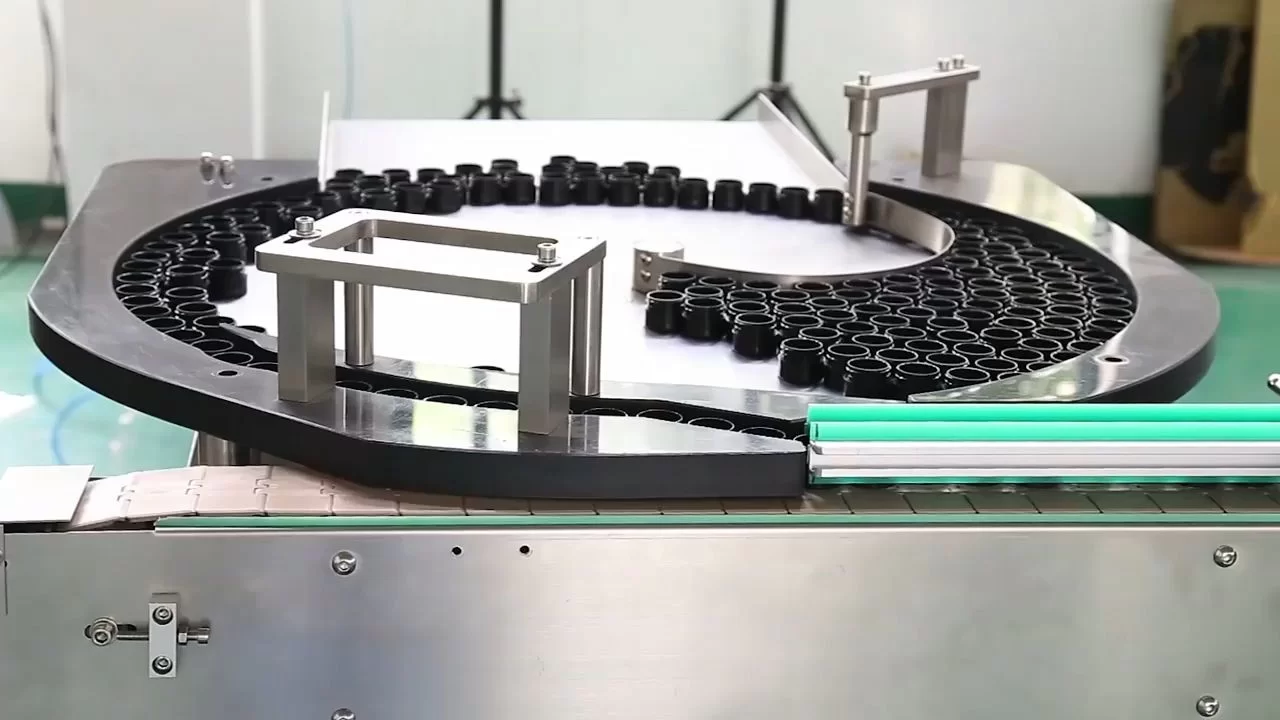

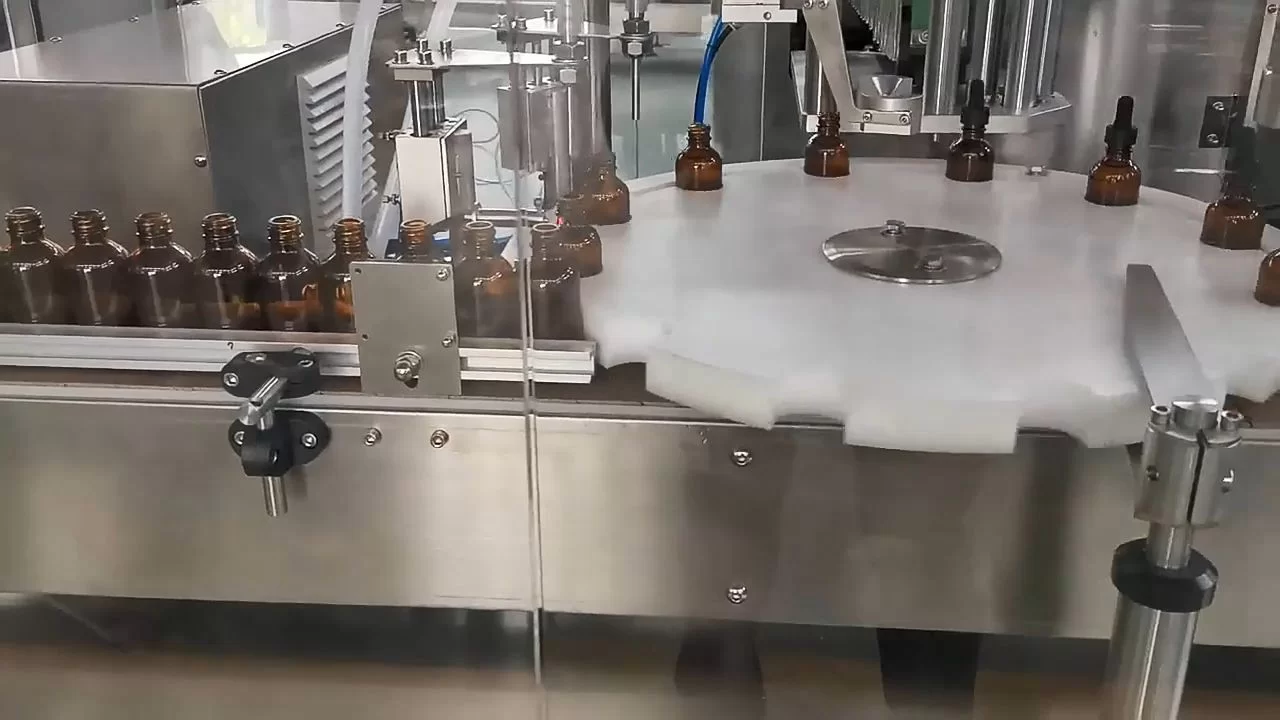

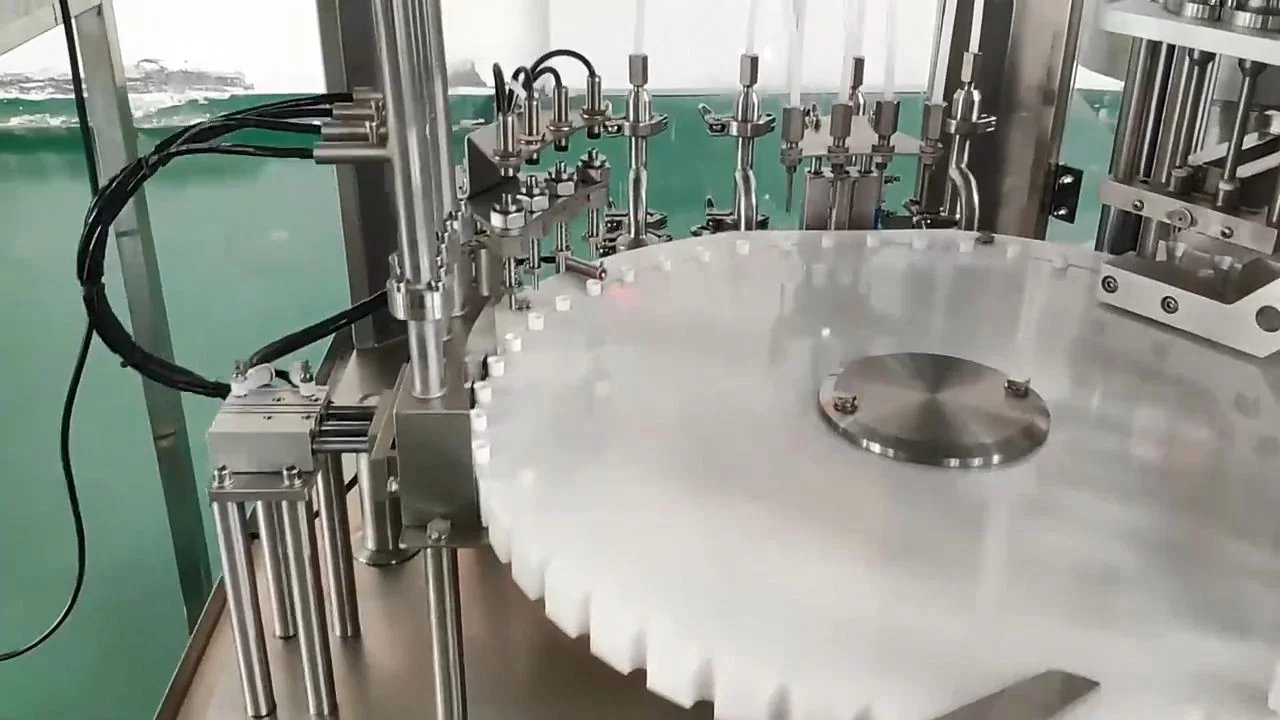

Eyedrop filling, plugging &capping machine for the application of round eyedrop bottle or similar ones, auto accomplish product filling, plug place, cap place, cap screw-on. The machine is composed by a load turntable, ceramic piston pump (alternative peristaltic pump) &fill nozzles, plug &cap sorter, Plug &cap placer, cap screw-on system, unload tray. The bottle loading/unloading is done manually, through loading turntable Ø500mm and unloading tray, or directly from an production line. It is designed and made accordance to GMP regulation.

1. the capacity of the eye filling machine is range from 80b/hour to100 bottles per hour

2. the filling volume of the machine is range from 5ml to 200ml

| Kind of bottle | Round eyedrop bottle or similar | |

| Bottle size* | Min. Ø 20mm Max. Ø30mm | |

| Speed | 100~150bpm on 5ml-20ml | |

| Filling volume* | 5ml~20ml | |

| Filling accuracy | ±2% | |

| Power* | 220V 50/60Hz 1.5kw | |

| Machine size mm | Length 2500, width 1420, height 1500 | |

| Compress air require | 50~70L/min, 4~6bar | |

| Machine weight: | 900kgs | |

Main features

1. The eye drop filling machine is controlled by PLC, stable and reliable; Touch screen human-computer interface, easy to operate;

2. eye drop filling machine has high temperature and high pressure resistant food grade pipes and quick joints, which is easy to dismantle and clean.

3. No bottle, no filling function, filling number counting function.

4. CIP function.

5. High measurement accuracy, filling error rate ≤ ± 1%.

6. Piston pump filling, high filling accuracy.

7. Manufactured according to the new GMP standard.

This machine is a state-of-the-art piece of equipment designed to provide a fully automated solution for filling and capping eye drop bottles in the 5ml to 30ml range. With its advanced technology and precision engineering, it is capable of filling and capping up to 120 bottles per minute, making it ideal for high-volume production environments.

The Full Automatic 5ml-30ml Eye Drop Filling and Capping Machine is equipped with a range of features designed to ensure accuracy and efficiency. These include a high-speed filling system, an advanced capping mechanism, and a user-friendly interface that allows for easy operation and maintenance.

The filling system of this machine utilizes a peristaltic pump that ensures accurate filling of each bottle, while also minimizing the risk of contamination. The capping mechanism utilizes a torque control system that ensures consistent and secure capping of each bottle, eliminating the risk of leaks or spills.

This machine is also designed with ease of use in mind, featuring a user-friendly interface that allows operators to quickly and easily adjust settings and perform routine maintenance tasks. Additionally, it is built with high-quality materials and components, ensuring reliable performance and durability.

Overall, the Full Automatic 5ml-30ml Eye Drop Filling and Capping Machine is an excellent choice for companies looking to improve their eye drop production efficiency and accuracy. Its advanced technology, precision engineering, and user-friendly design make it a standout piece of equipment in the packaging industry.