Automatic linear capping machine, it is applicable for round, square & flat bottle it is used in many industries, such as cosmetic, food and pharmaceutical.The caps are round with diameter 12mm-120mm.

MAIN FEATURE

1. Suit to various bottles and round caps.

2. No need to change parts, easy operation and adjust, low maintenance.

| 1 | Model | VK-LC | |

| 2 | Applied bottle range | 100ml-1000ml 1000ml-5000ml | |

| 3 | Applied cap size | Dia:12-120mm | |

| 4 | Yield of capping | >99% | |

| 5 | Power Supply | 220V 50HZ | |

| 5 | Power Consumption | <2KW | |

| 6 | Air Pressure | 0.4-0.6Mpa | |

| 7 | Speed Control | Frequency Conversion | |

| 8 | Single machine noise | <=70Db | |

| 9 | Weight | 850kg | |

| 10 | Dimension (LxWxH) | 2000x1100x1800(mm) | |

| 11 | Production Capacity | 5000-7200 bottles/h | |

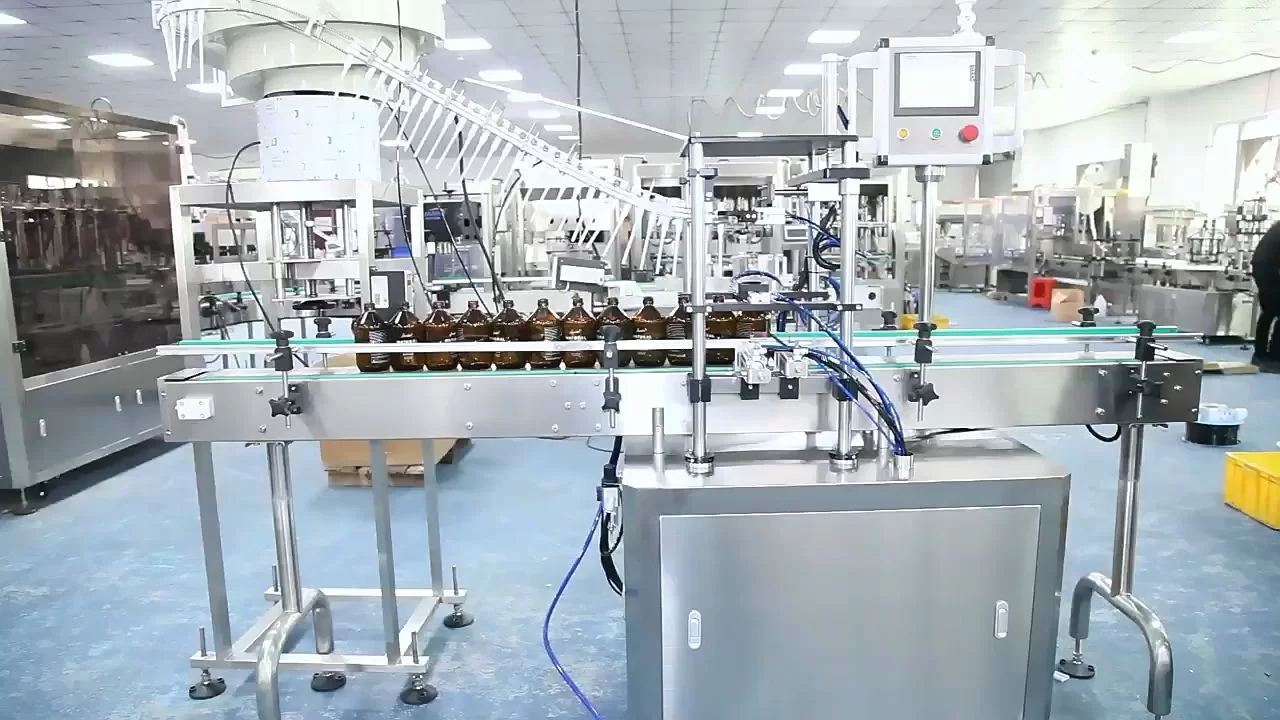

Fully Automatic Oil Bottle Press Capping Machines are a powerful and efficient way to unlock the potential of any production line. These machines are designed to quickly and accurately apply caps to bottles with a variety of shapes and sizes, allowing for faster throughput and higher quality products. The machines use advanced technology such as servo motors, pressure sensors, vision systems, and programmable logic controllers (PLCs) to ensure accuracy and reliability. They also feature user-friendly interfaces that make them easy to operate. With their high speed operation, robust construction, and low maintenance requirements, these machines are an ideal choice for any production line looking to increase efficiency while maintaining product quality.

Exploring the Benefits of Fully Automatic Oil Bottle Press Capping Machines

Fully Automatic Oil Bottle Press Capping Machines are an essential piece of equipment for any oil bottling facility. These machines provide a reliable and efficient way to cap bottles quickly and accurately, allowing businesses to increase their production speed while maintaining quality standards. The fully automatic nature of these machines eliminates the need for manual labor, saving time and money in the long run.

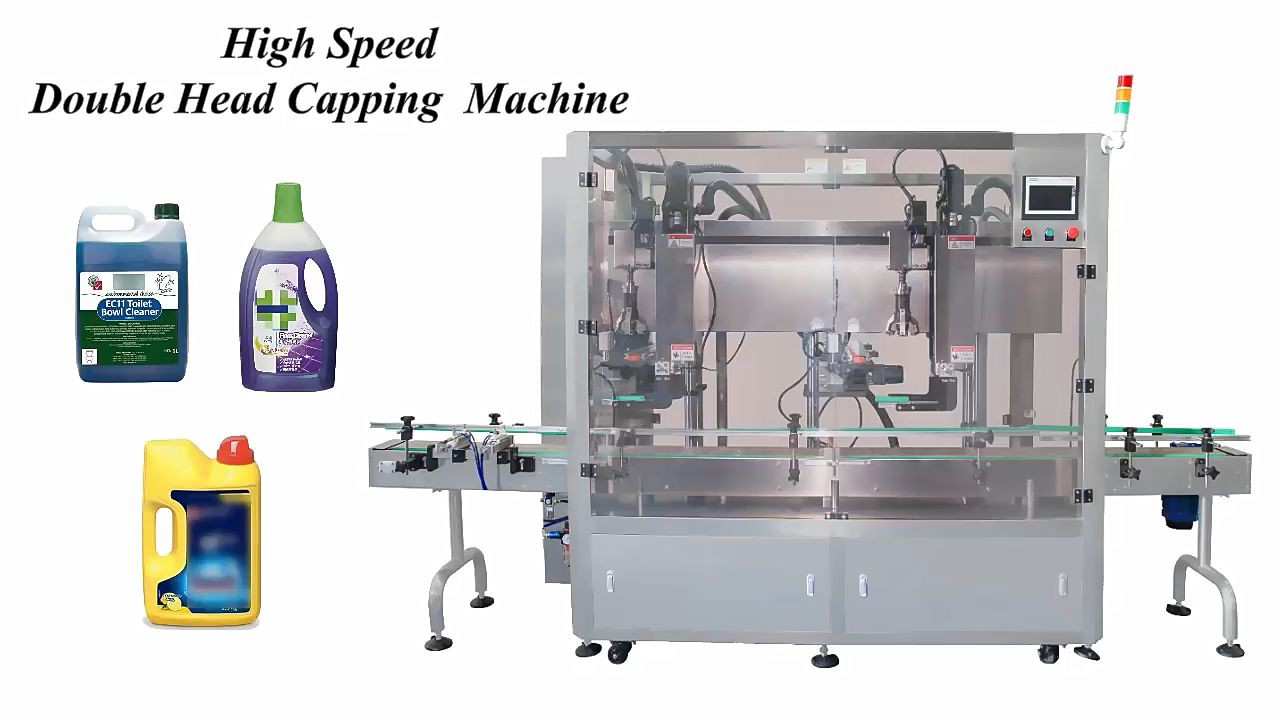

These machines feature a range of features designed to improve efficiency and accuracy, such as adjustable speed settings, adjustable capping pressure settings, and built-in safety features. They also come with a variety of interchangeable parts that can be used to accommodate different bottle sizes or shapes. This ensures that all bottles are capped correctly without any errors or damage caused by incorrect capping pressure or improper alignment.

The benefits of using Fully Automatic Oil Bottle Press Capping Machines extend beyond just increased production speeds; they also reduce labor costs associated with manual capping processes, eliminate potential errors caused by human error, and help maintain product quality standards throughout the entire bottling process. Furthermore, these machines require minimal maintenance compared to manual processes due to their robust construction and easy-to-use design.

Understanding the Technical Aspects of Fully Automatic Oil Bottle Press Capping Machines

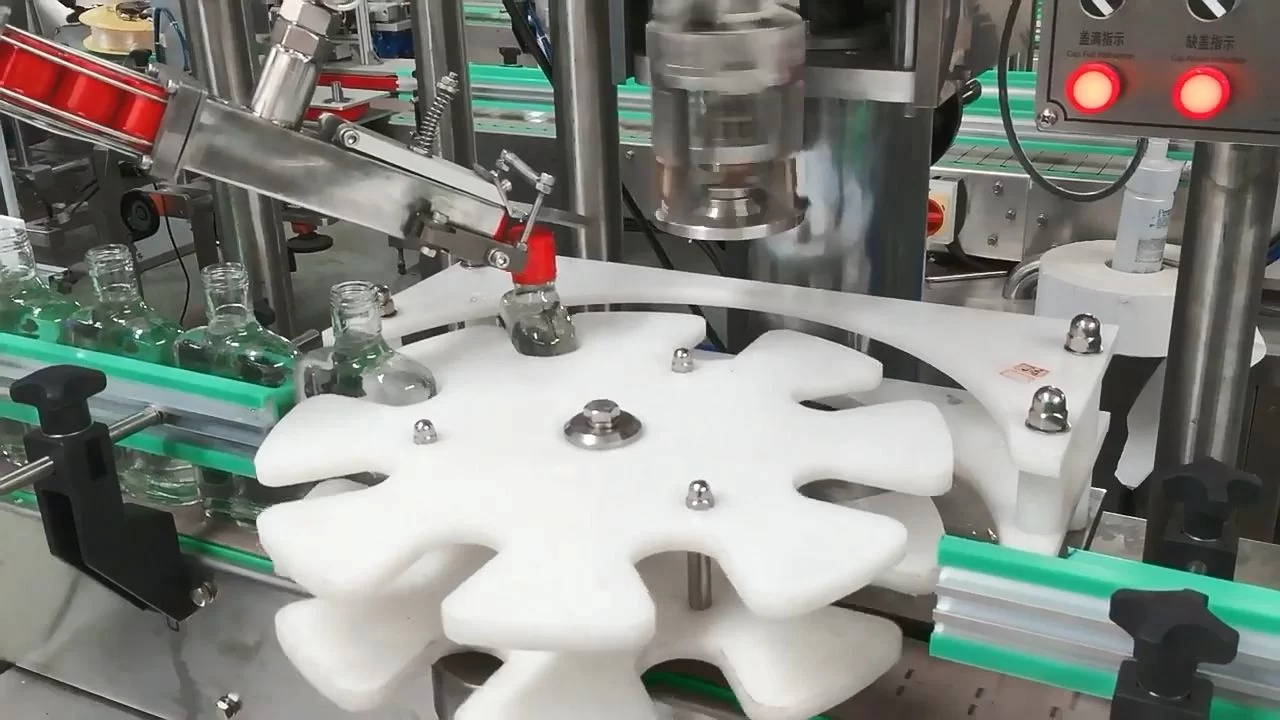

Fully Automatic Oil Bottle Press Capping Machines are advanced, automated systems designed to quickly and accurately cap oil bottles. These machines feature a range of components that work together to ensure the proper application of caps onto containers. The process begins with the loading of empty bottles onto the machine's infeed conveyor belt. As the bottles move along, they pass through a series of rollers which orient them for capping. Once in position, an automated capping head applies pre-measured caps onto each bottle before it is released from the machine and sent down a chute for further processing or packaging.

The capping head is typically driven by an electric motor and can be adjusted to accommodate different sizes and shapes of caps as well as different bottle diameters. This ensures that each cap is applied securely and consistently with minimal effort from operators. Additionally, many machines feature adjustable speed settings so users can customize their production rate according to their needs.

Fully Automatic Oil Bottle Press Capping Machines are reliable solutions for businesses looking to streamline their bottling operations while ensuring accuracy and consistency in their product quality control processes. With features such as automatic orientation, adjustable speed settings, precise torque control, quick changeover times between different size containers or caps, these machines offer high performance capabilities that help businesses save time and money while delivering superior results every time.

Optimizing Performance Through Automation in Oil Bottle Press Capping Machines

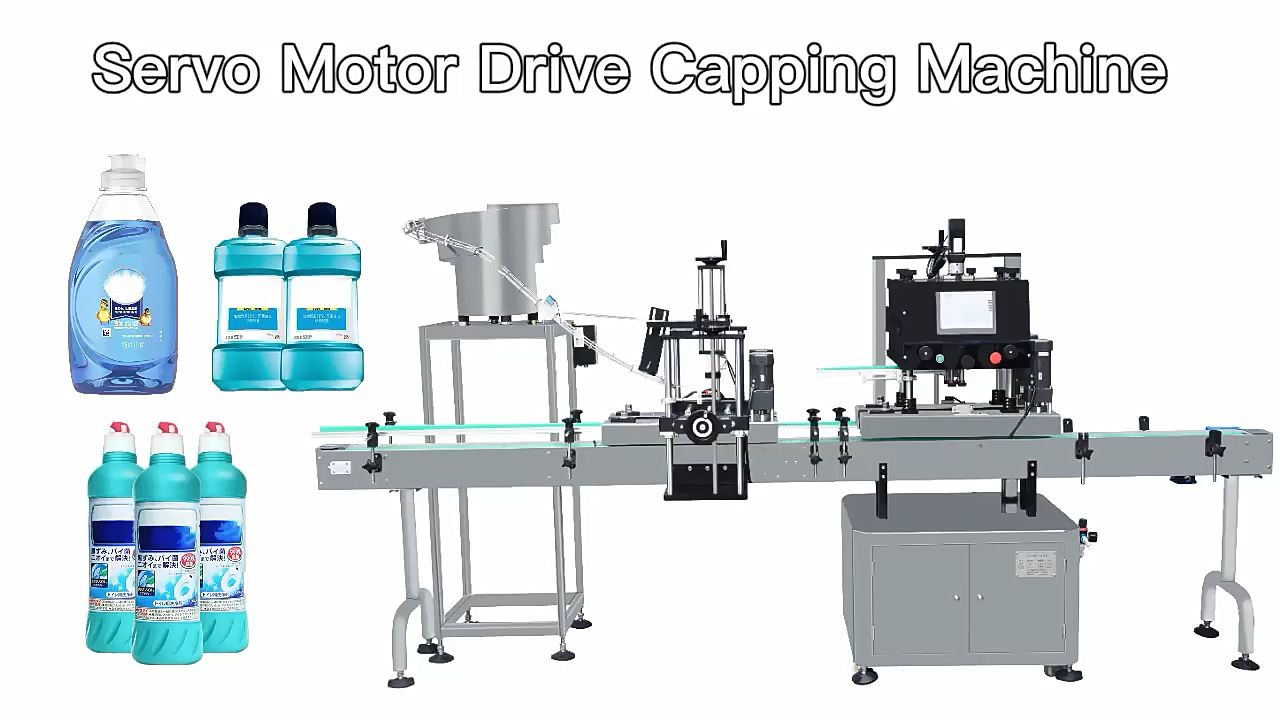

Automation in oil bottle press capping machines is an effective way to optimize performance. This type of automation utilizes advanced technologies such as servo motors, sensors, and controllers to ensure that the machine operates at maximum efficiency. Automation allows for faster production speeds and improved accuracy, resulting in a higher quality product with less waste. Additionally, automated machines require less maintenance and can be operated with minimal supervision.

Servo motors are used to control the speed of the machine’s movements, ensuring that it runs at a consistent rate throughout the process. Sensors detect when bottles are properly positioned for capping and activate the appropriate machinery accordingly. Controllers provide feedback on system performance so operators can make adjustments as needed for optimal operation.

Automated oil bottle press capping machines offer numerous benefits over manual operations including increased safety, improved accuracy, reduced labor costs, and enhanced production speeds. By optimizing performance through automation, manufacturers can reduce costs while producing a higher quality product in less time than ever before.

Analyzing Efficiency Gains with Fully Automatic Oil Bottle Press Capping Machines

Fully Automatic Oil Bottle Press Capping Machines are an efficient and cost-effective way to improve production line performance. These machines are designed to quickly and accurately cap bottles with a variety of oil types, from motor oil to cooking oil. They offer a number of advantages over manual capping methods, including improved accuracy, increased speed, reduced labor costs, and fewer safety risks. By analyzing the efficiency gains associated with these machines, businesses can determine if they are the right choice for their operations.

The primary benefit of using Fully Automatic Oil Bottle Press Capping Machines is that they provide faster and more accurate capping than manual methods. The machines use precision rollers to apply even pressure on each bottle’s cap during the capping process. This ensures that each bottle is properly sealed without any leakage or contamination risk. Additionally, these machines can be programmed to accommodate different sizes and shapes of bottles for greater versatility in production lines.

Fully Automatic Oil Bottle Press Capping Machines also reduce labor costs by eliminating the need for manual capping processes which require additional staff members for supervision and operation. In addition, these machines help reduce safety risks associated with manual capping processes by reducing operator fatigue due to repetitive motions as well as eliminating potential hazards from mishandling bottles or caps during the process.

By analyzing efficiency gains associated with Fully Automatic Oil Bottle Press Capping Machines businesses can determine if they are a suitable solution for their operations based on cost savings versus traditional manual methods as well as other factors such as accuracy rate and speed of production line output.

Examining Cost Savings of Fully Automatic Oil Bottle Press Capping Machines

Examining the cost savings of fully automatic oil bottle press capping machines is a critical part of any production process. These machines are designed to quickly and accurately apply caps to oil bottles, reducing labor costs and increasing efficiency. Fully automatic oil bottle press capping machines use a combination of mechanical, electrical, and pneumatic components to create an automated process that is faster than manual methods. The machine utilizes a set of rollers that apply pressure to the cap in order to secure it tightly onto the bottle. This method reduces the risk of leakage or contamination from improperly sealed bottles. Additionally, these machines are able to cap multiple bottles at once, which further increases efficiency and reduces labor costs associated with manual capping processes. Examining the cost savings associated with fully automatic oil bottle press capping machines can help businesses determine if investing in this technology is right for their operations.

Conclusion

Fully Automatic Oil Bottle Press Capping Machines are a valuable asset to any business that needs to package oil bottles quickly and efficiently. These machines can reduce labor costs, increase production speed, and provide consistent capping quality. With the ability to adjust the pressure settings for different bottle sizes, these machines can be used in a variety of applications. Additionally, their robust construction ensures long-term reliability and performance. Unlocking the potential of these machines is sure to bring about significant cost savings and improved productivity for any business.